Hello friends, in today’s article, we are going to talk about what Lightning Arresters are, what their types are, and what are their advantages and disadvantages.

What are Lightning Arresters?

Lightning Arresters are a device used to protect from lightning strikes. These are known as Lightning Arresters. An electric shock is nothing but a temporary increase in voltage, arc, spark, and surge current caused by electricity.

With the help of this tool, the surge current is lowered into the ground to provide security to the device. The system can also protect power systems and overhead lines from ground wire or direct electric shocks using earrings. The device is designed in such a way that towers or transmission poles and buildings can be used to safely lower excess voltage and discharge currents into the ground.

Lightning Arrester Working Principle:

Lightning Arresters The principle is that once the voltage surge travels across the conductor and reaches the place where it is to be installed. So it will break the insulation of the conductor for a moment so that the voltage surge can be discharged toward the ground.

Once the system is less than the voltage, the insulation will be re-established between the ground and the conductor. The current flowing towards the ground is turned off.

Suggested Read: What Is Electrical Grounding? | The Definitive Guide

Types of Lightning Arresters:

Lightning Arresters are used to protect electrical equipment from lightning. It is placed very close to the device. When lightning strikes, it lowers its high voltage to the ground. The choice is based on various factors such as voltage, current, reliability, etc., some of which are listed below.

| Sr. No. | Lightning Arrester Types |

| #1 | Road Gap Arrester |

| #2 | Sphere Gap Arrester |

| #3 | Horn Gap Arrester |

| #4 | Multiple-Gap Arrester |

| #5 | Impulse Protective Gap |

| #6 | Electrolytic Arrester |

| #7 | Expulsion Type Lightning Arrester |

| #8 | Valve Type Lightning Arrester |

| #9 | Thyrite Lightning Arrester |

| #10 | Auto valve Arrester |

| #11 | Oxide Film Arrester |

| #12 | Metal Oxide Lightning Arresters |

#1. Road Gap Arrester:

The design of this Arrester is straightforward and simple. This type of Arrester has an air gap between the ends of the 2 rods. The air gap setting of this Arrester is set in such a way that it breaks before any damage is done to it. When the line has a high voltage. So that there is a spark in the distance and the current of excess goes down to the ground. So the equipment is protected from damage.

The trouble with this Arrester is that once the spark is ignited, it can continue for a while, even at low voltage. This uses a limited current reactor in series with the rod for protection. The barrier limits the current to a certain extent that it is sufficient to maintain the arc.

Another problem with road intervals is that the arc temperature is responsible for damaging the rod due to the high temperature, which can cause the rod to melt.

Suggested Read: What Is an Oil Circuit Breaker | Construction of Oil Circuit Breaker

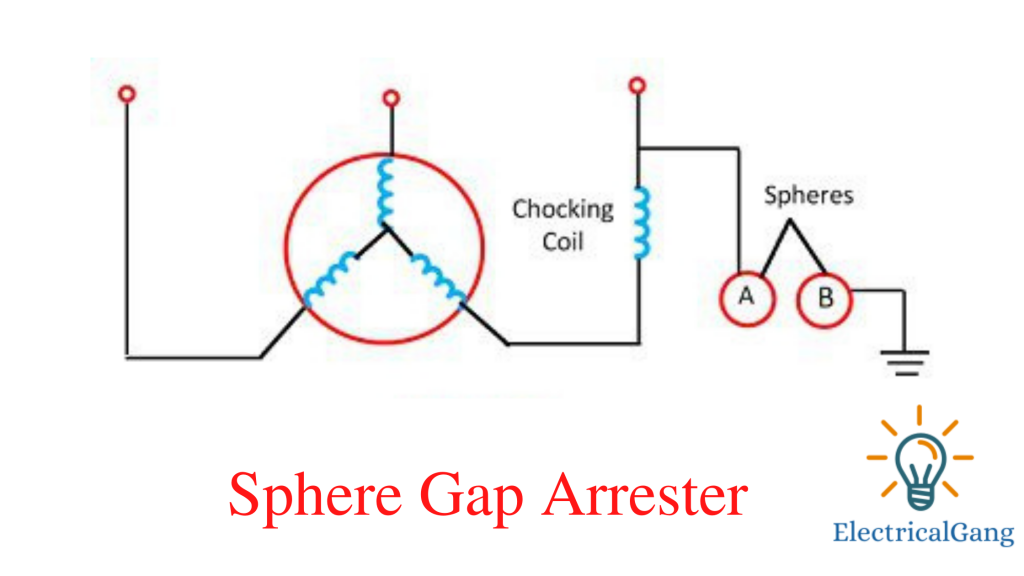

#2. Sphere Gap Arrester:

In devices of this type of Arresters, air distances are given in two different areas. One sphere is connected to the line, and the other sphere is attached to the ground. The distance between these two areas is kept very short. A suffocating coil is passed between the phase windings of the transformer and connected to the sphere line.

The Arresters and Air No Gap are set so that the discharge does not occur in normal operating conditions as the arc will travel in the vicinity as the hot air near the arc tends upwards and along the length until it is automatically interrupted.

The Arresters and Air No Gap are set so that the discharge does not occur in normal operating conditions as the arc will travel in the vicinity as the hot air near the arc tends upwards and along the length until it is automatically interrupted.

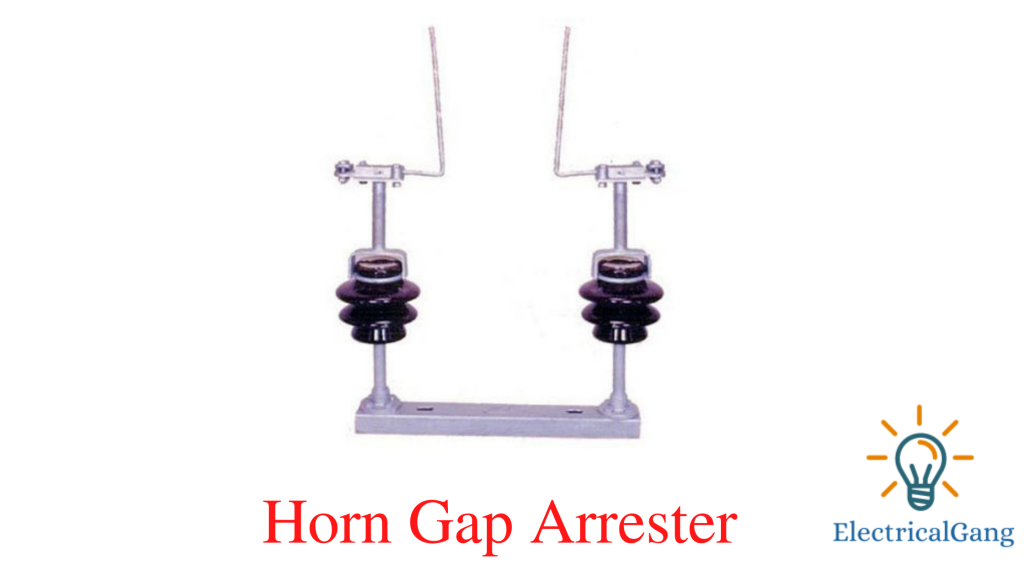

#3. Horn Gap Arrester:

These Arresters are made of horn-shaped pieces of metal. Which is separated by a medium of very low air. And each line is arranged in such a way that it stays close to the earth. Thus the distance between the two electrodes is such that it does not earth between the line and earth in normal conditions, but if the voltage increases, it will break the distance and hence the earthing path. Will find.

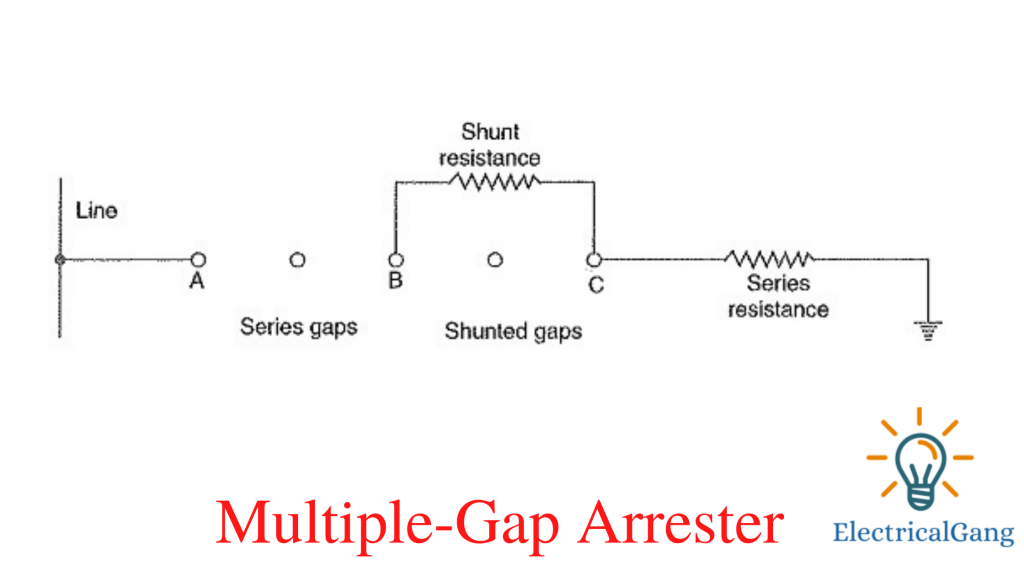

#4. Multiple-Gap Arrester:

Arresters of this type are designed to be small metal cylinders in series. Which are separated from each other by means of air and are insulated from each other.

Arresters of this type are designed to be small metal cylinders in series. Which are separated from each other by means of air and are insulated from each other.

Whose first cylinder is connected to the line and the last and its next cylinder in series connected to the earthing. The intermediate cylinder has a shunt barrier at some intervals. The distance between the cylinders depends on the voltage of the line.

#5. Electrolytic Arrester:

Arresters of this type have a large discharge capacity only. It works in such a way that a thin strip of aluminum hydroxide is deposited on the electrolyte completely immersed in the aluminum plates. The plate acts as high resistance to low cost but fixed value. Less resistance to voltages than. Puncture at a voltage of more than 400 volts causes the free flow of current to the earth.

When the voltage remains at its normal value of 440 volts, the arrester again provides high resistance in the path and stops the leakage.

Suggested Read: Whirlpool Dishwasher Not Washing – Possible Causes and Solutions

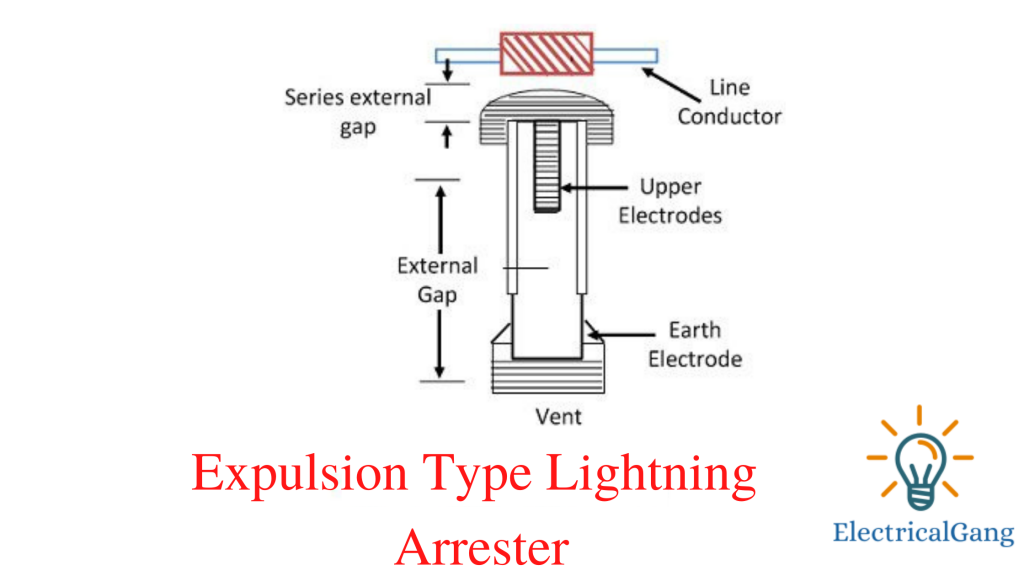

#6. Expulsion Type Lightning Arrester:

Arresters of this type have an improvement in the distance of the rod in which it shuts off the frequency of power. This air raster uses a tube made of very effective fiber to separate the spark gap and the interrupted spark gap inside the fiber tube.

The spark of impulse inside the fibrous tube during operation destabilizes some of the fibrous material of the arc tube in the form of gas, which is called a vent from the bottom of the tube. Thus, extinguishing the arc is just like circuit breakers.

#7. Auto valve Arrester:

This type of arrester consists of several flat discs of mesh material that are mounted on top of one and separated by thin mica rings. Disk content is not homogeneous, and admin content has also been added. So the glow discharge occurs in the capillaries of the material, and the voltage drops to about 350 volts per unit. The disk is configured in such a way that normal voltage does not cause discharge.

#8. Valve Type Lightning Arresters:

This type of arrester applies to electrical systems that are more powerful. These devices consist of two main parts, the sequence of spark gaps as well as the series of non-linear resistor disks. These devices can operate whenever a high voltage spark strikes the gusset and the non-linear resistors have a grounding voltage. Whenever the surplus power surge stops, the spark gaps can be pushed apart by the resistors.

Advantages of Lightning Arrester:

The benefits of Lightning Arrester are as follows:

- Damage caused by lightning can be minimized.

- Easy to use.

- Provides protection of equipment outside the substation.

- Damage to the overhead line can be avoided.

- Outlet surgeries can be avoided.

- Electromagnetic interference.

Disadvantages of Lightning Arrester:

The Disadvantages of Lightning Arrester are as follows:

- Prevents excessive space in the line.

- Installation costs are higher.

Like this post? Could you share it with your friends?

Suggested Read –

WHEN your home has a lightning arrestor . Is it safe or is there still a danger of dying?

it is safe from lightning arrestor

Lightning arresters are a great way to protect your home and property from lightning damage.