What is a Squirrel Cage Induction Motor?

The squirrel cage induction motor is the same type of 3 phase induction motor. Which is a function beyond the principle of electromagnetism The rotor inside the motor is known as the squirrel cage rotor? This is known as the squirrel cage induction motor as its entire shape is similar to the squirrel cage.

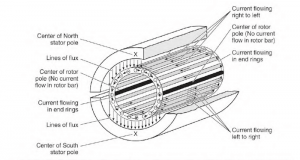

Thus the rotor is a type of steel cylinder nose. In which every electric current can pass across its surface, such as copper or aluminum is used. When AC is passed through the stator winding, a magnetic field is generated in it. Due to this process current is generated due to winding in the rotor. Which produces its magnetic field. The magnetic field of the stator and rotor produces torque.

The biggest advantage of a squirrel cage induction motor is that you can easily change its speed and torque. This can be done by adjusting the shape of the bars in the rotor in advance.

Also Read: Best Pole Changing Method Of Speed Control Of Induction Motor

Principle of Squirrel Cage Induction Motor:

When the stator winding is supplied, the rotating magnetic field is set. This is the motion of the rotating magnetic field called synchronous speed. This rotating magnetic field excites the voltage in the rotor bar so that a short circuit current is passed through the rotor bar. I Will try so the rotor follows the rotating magnetic field.

At this point, the rotor rotates the magnetic field pulling the rotor current to zero. This is because there is no relative motion between the rotating magnetic field and the rotor. At that moment the rotor experiences zero tangential force.

After the speed of the rotor decreases, the motion between the rotor and the rotating magnetic field is re-established, from which the tangent force is re-established for the rotation of the rotor. So again the rotor starts rotating the magnetic field at the following position, and in this way, the rotor maintains a constant speed which is slightly less than the speed of the rotating magnetic field or synchronous motion.

Slip is a measure of the difference between the speed of a rotating magnetic field and the speed of a rotor.

Rotor current frequency = Slip × Supply frequency.

Also Read: What is Electric Motor? | Different Types of Electric Motors

Construction of Squirrel Cage Induction Motor:

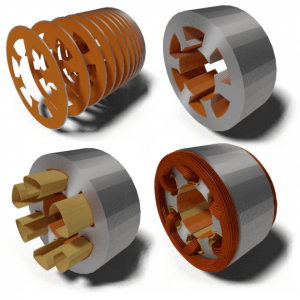

The squirrel cage induction motor consists of the following parts:

- Stator.

- Rotor.

- Fan.

- Bearings.

#1. Stator:

Thus laminated core and metal housing have been used and this includes 3 phase winding. Inside, the winding is arranged so that an angle of 120o between the three phases is arranged.

#2. Rotor:

A rotor is a part of a motor that will be in circulation to provide a mechanical output for a given amount of electrical energy. How many ratings does the motor have and its output is mentioned by nameplate? Shaft, short-rotating copper/aluminum bar Included.

The rotor core is laminated which results in a reduction in eddy current loss and hysteresis loss. The conductors are skipped to prevent coagulation when starting operation and give a better transition ratio between the stator and the rotor.

#3. Fan:

The fan is fitted to the rear of the motor. So that it is easy to control the temperature of the motor.

#4. Bearing:

Batteries are provided as the basis of rotor speed, and bearings maintain smooth rotation of the motor.

The Usefulness of Squirrel Cage Induction Motor:

The use of this motor, in general, is found to be excessive in industrial units. This is also designed and suitable where the speed of the motor has to be constantly maintained and should be self-starting, or there is a desire for low maintenance.

General use of squirrel cage induction motor

- Centrifugal pump.

- Industrial drives (e.g. to operate conveyor belts).

- Big blow and fans.

- Machine tools.

- Lathes and another turning tool.

Also Read: Double Cage Rotor of Induction Motor

Advantages of Squirrel Cage Induction Motor:

The advantages of a squirrel cage induction motor are as follows:

- This runs at a low cost.

- There is no special need for knowledge.

- Able to maintain a constant speed.

- Provides high functionality.

- Small and lightweight.

- Explosion-proof.

- Efficiency.

Non-Advantages of Squirrel Cage Induction Motor:

The squirrel cage induction motor is as popular as it has its advantages and disadvantages. Although they have very poor speed control and are energy efficient when running at full load current, they consume a lot of power at startup.

They are more sensitive to fluctuations in supply voltage. When the supply voltage decreases, the induction motor draws more current. During voltage surge, the increase in voltage satisfies the magnetic components of the squirrel cage induction motor.

Also Read: What is Stator | Construction Of Stator | Working Principle Of Stator | Applications Of Stator

Squirrel Cage Induction Motor Classification:

Nema (National Electrical Manufacturers Association) in the United States and IEC in Europe have classified the design of speed-cage induction motors into several classes based on their speed-torque characteristics such as Class A, Class B, Class C, Class D, Class E, and Class F.

Class A Design:

- A normal starting torque.

- A normal initial flow.

- Low slip.

- In this class, pullout torque is always 200 to 300 percent of the full load torque and it occurs at low slip.

- For this class, the starting torque is equal to the rated torque for large motors and about 200 percent or more rated torque for small motors.

Class B Design:

- Normal starting torque,

- Lower starting current,

- Low slip.

- This class of induction motor produces the same initial torque as the class A induction motor.

Class C Design:

- High starting torque.

- Low starting current.

- Low slip at full load (less than 5%).

- Up to 250 percent of full load torque, initial torque is in this class of design.

Like this post? Could you share it with your friends?

Suggested Read –

- Difference Between MCB and MCCB | MCB VS MCCB

- Star to Delta Conversion and Delta to Star Conversion

- Types of Losses in a Transformer | Efficiency Of Transformer

- What is a MOSFET | Construction Of MOSFET | Working Principle Of MOSFET | Types of MOSFET | Applications Of MOSFET

- What is a Clamp Meter | Construction of Clamp Meter | Working Principle of Clamp Meter | Application of Clamp Meter