Hello friends, in today’s article we will talk about Double Cage Rotor. Let’s see what this is.

Double Cage induction motor is a type of motor that uses double cage or double rotor winding. Such a system is used to get more torque in less current

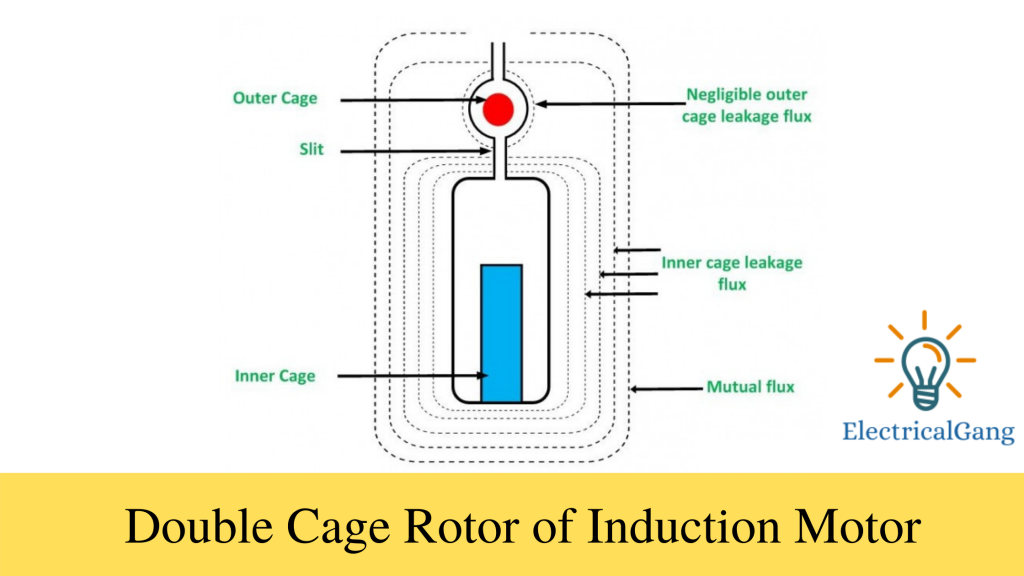

The stator of this motor is also the same as that of a normal induction motor. In the double cage rotor of the induction motor, there are two layers of bars. You can see the figure of the Double Cage induction motor below

Each winding is shorted by the final rings. In the outer cage, a small cross-section is made compared to the inner bar. And they are made of highly resistant materials like brass, aluminium, bronze, etc.,

The inner cage bars are made of low insulating copper. Thus, the resistance of the outer cage is greater than the resistance of the inner cage.

There is a gap between the slot at the top and the bottom. Thus, there is more self-induction in the inner winding.

Also Read : MCB Types and it’s Uses

Initially, the voltage generated in the rotor is the same as the given voltage. The leakage action of the winding in the inner cage is much larger compared to the winding in the outer cage.

The termination in the outer cage carries the starting current which gives less impediment to the flow of the current. High resistance winding in the outer cage, therefore, develops higher initial torque.

As the speed of the rotor of the motor increases, the frequency of rotor EMF (fr = sf) decreases. At ordinary operating speeds, the leakage reaction of both windings becomes negligibly small.

The current in the rotor is divided into both cages and is driven by their resistance. The colluctation of the outer cage is about 5 to 6 times that of the inner cage. Therefore, the torque of the motor is mainly developed by the inner cage of low colluctation and develops under normal operating speed.

For low starting torque requirements, a common cage motor is used. A cold bar cage motor is used for more torque requirements.

A double cage rotor motor is used for high torque. Slip ring construction is used for motors of large size. The initial torque and initial duration are also large.

Also Read :

Squirrel Cage Induction Motor Working Principle & Applications

What Is Static Kramer Drive | Definition And Working Method

What Is DC Generator | Types Of DC Generator

What is Earthing And Types of Earthing

Printed Circuit Board (PCB) Motor