Hello friends, in today’s article, we will see what the advantages of PCB motors are and what their uses are.

Introduction:

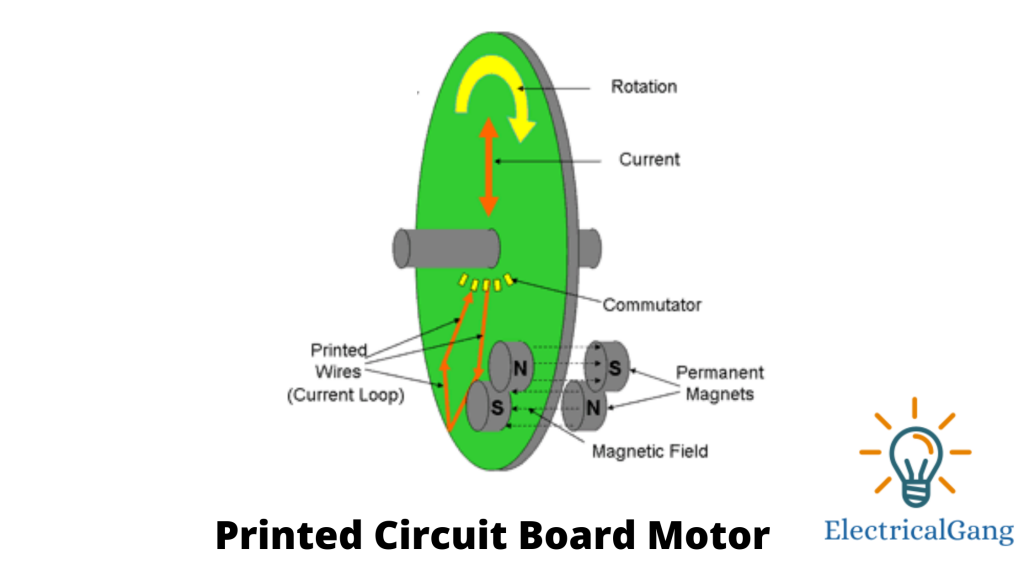

The Printed Circuit Board consists of a rotor disc made of non-magnetic and non-conductive material. The armature winding and the commutator are printed on both sides of the plate with the help of copper. The disc is placed between two sets of permanent magnets mounted on ferromagnetic plates on the armature. The brush is placed inside the motor.

The axial current is generated by the armature due to the adjustment of the inside of the motor. The torque in the motor is generated by the interaction of the axial current and the current flowing through the armature disc.

Advantages of Printed Circuit Board Motor:

- The motor starts and stops at high speed due to its low inertia and high inertia and torque.

- The motor rotor has no iron parts, so it has low armature inductance.

- Low armature induction reduces sparking and increases the life of the brush.

- Cogging torque is absent because of the non-magnetic rotor.

- The PCB motor maintains a high current capacity.

Application of Printed Circuit Board Motor:

- The characteristic of PCB motor, i.e., high torque and inertia ratio, makes the motor suitable for handling applications.

- High-speed tap is read.

- Such a motor is used in X-Y records point-to-point tool positioner.

- It is perfect for heavy-duty drives.

- Robotics and other servo drives are thus used.

Like this post? Could you share it with your friends?

Suggested Read –

Sub : PCB Motor

Hi Vishnu Patil, Firstly wanted to commend you for keeping this window open for learning and sharing.

Myself Sujesh Mangot from Mumbai. Iam a market consultant.

I would appreciated if you can give me a few more specific details on PCB motor. I would like to have a brief conversation with you are your convenience.

Do let me know if its feasible for you.