The first report of vacuum interceptor technology was made in 1960. This technology has been evolving from 1960 to the present day. As the days went by, the size of the vacuum interrupter has shrunk since the early 1960s due to the development of various technologies in the field of engineering. A circuit breaker is one such device. Which interrupts the electric circuit to prevent irregular flow due to a short circuit.

Usually the result of overload. The main function is to detect the defect and then interrupt the current flow. In today’s article, we will see what is Vacuum Circuit Breaker, why Vacuum Circuit Breaker is constructed. What is the working principle of a Vacuum Circuit Breaker and what is the application of the Vacuum Circuit Breaker and the Types of the circuit breaker?

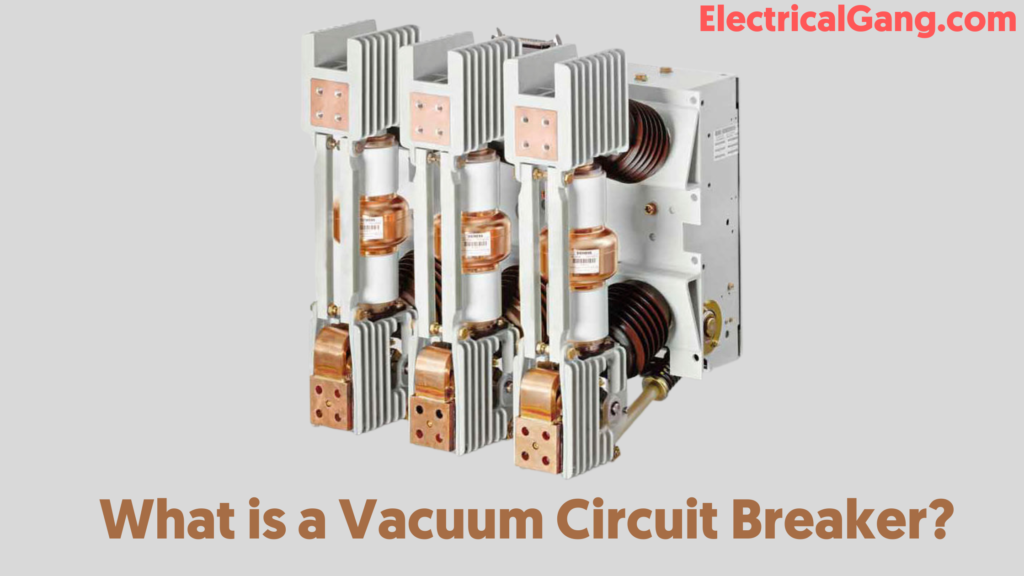

What is a Vacuum Circuit Breaker?

Vacuum Circuit Breaker is a special type of circuit breaker. In which arc quenching is done by means of a vacuum. Operation and closure of current-carrying contacts and arc-related disturbances occur in a vacuum chamber of this breaker. Which is known as a vacuum interrupter.

A vacuum used in a circuit breaker as a means of arc quenching is known as a vacuum circuit breaker. This is because the vacuum superior arc gives high insulating strength due to its decorative properties. Most of these are suitable for standard voltage applications. This technique was developed only for high voltage. Although it is not commercially possible.

The current-carrying conductor and its corresponding arc interruption are operated inside the vacuum chamber of the breaker. Which is known as a vacuum interrupter. A steel arc chamber is included in the center of this resistively symmetrical ceramic insulator. The vacuum pressure inside the vacuum interrupter is maintained at 10–6 bar. Vacuum circuit breaker operation mainly depends on the material used for current-carrying contacts.

Suggested Read: Difference Between Circuit Breaker and Isolator

Working Principle of Vacuum Circuit Breaker:

The working principle of the Vacuum Circuit Breaker is that once the circuit breaker is opened inside the contact vacuum, an arc can be generated between the contacts by ionization of the metal vapor in the contact. But the arc can be easily extinguished. This is because fast electrons, ions, and metallic vapor are generated in the outer part of the circuit breaker contact so that dielectric strength can be achieved quickly.

The most important feature of a vacuum is that once an arc is generated inside the vacuum, it can be quickly extinguished due to the rate of rapid improvement in the dielectric strength of the vacuum.

Contact Materials of Vaccum Circuit Breaker:

Vacuum Circuit Breaker contact materials must adhere to the following properties.

- Contact resistance must be low.

- High density.

- The electrical conductivity must be high to pass normal load currents without overheating of any kind.

- Increases thermal conductivity to quickly dissipate large amounts of heat generated during arcing.

- The thermionic function should be high to allow the destruction of the starting arc.

- The trend must be less welded.

- Low current chopped level.

- Resists high arc capacity.

- Boiling points should be high to prevent arc erosion.

- Gas content must be given below to ensure long service life.

Construction of Vacuum Circuit Breaker:

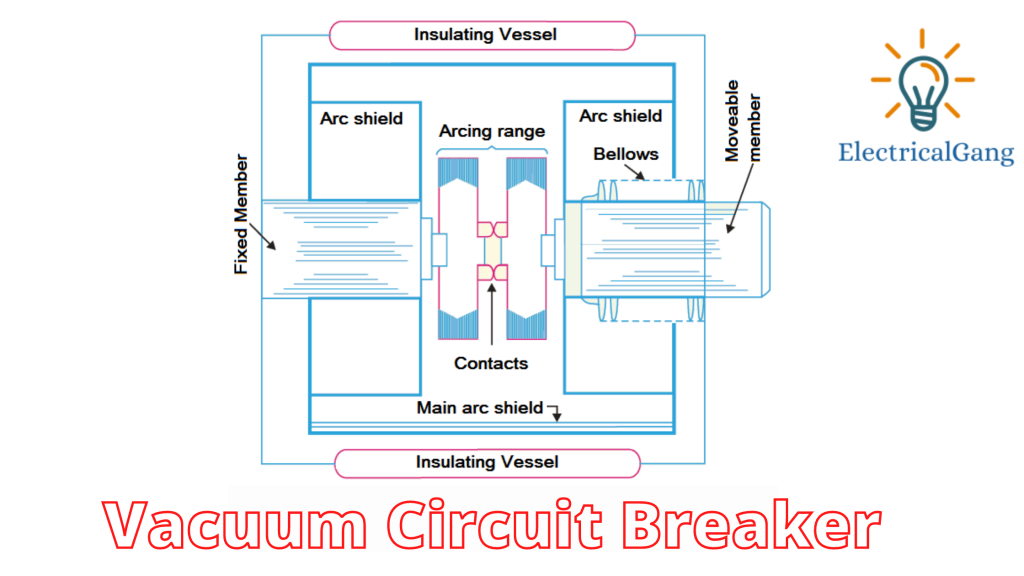

This circuit breaker consists of a steel arc chamber in a center-symmetrically arranged ceramic insulator. Thus the pressure inside the vacuum interrupter is maintained below 10 ^ -4 tor.

The material used in the current-carrying contact plays an important role in the performance of the Vacuum Circuit Breaker. Like alloys, copper-bismuth or copper-chrome is an excellent material for making VCB contacts.

The diagram of the Vacuum Circuit Breaker is shown above in which we can see that it has fixed contact and rotating contact. And includes a vacuum interrupter. The rotating contacts are connected to the control system by a stainless steel bellow.

The arc sealed is supported on the insulating housing as they cover the shields in this way. And is prevented from condensing on the insulating enclosure. Glass utensils or ceramic utensils are used as an external insulating body as the vacuum chamber is permanently sealed. So there is no possibility of leakage.

Working of Vacuum Circuit Breaker:

When a contact separates due to an abnormal circumstance, an arc is struck between the two contacts, which is due to the ionization of the metal ions and is highly dependent on the material of the contacts.

Arc dispersion in vacuum interrupters differs from other types of circuit breakers. Isolation of the contact causes the light to evaporate. Which fills in the contact location. It has positive ions separated from the contact material. The density of steam depends on the current of the arc. When the current decreases, the light rate of steam decreases.

After the current zero, if the vapor density is low the medium regains its dielectric strength. When the constrained current is very small in a vacuum, there are many parallel paths to the arc. Total currents are divided into several parallel arcs. Which repel each other and spread to the contact surface. This is called a scattered arc that can be easily disrupted.

Concentrated in a small area of the arc at a high value of current causes rapid evaporation of the contact surface. Disruption of the arc is possible if the arc is in a scattered state. If it is quickly removed from the contact surface, the arc will strike again.

Arc destruction in a vacuum breaker is greatly influenced by the material of the contact and the technique of considering the metal vapor. The path of the arc is changed so that the temperature does not rise at any stage.

After the final arc disruption, there is a rapid building of dielectric strength which is fantastic for a vacuum breaker. They are perfect for switching capacitors. Because it will perform re-strike-free. The small current is interrupted before the natural current zero, which can cause it to cut which level depends on the contact material.

Suggested Read: What are Semiconductor Devices? | Semiconductor Device Materials

Current Chopping:

Current chopping in a vacuum circuit breaker is mainly due to the instability of the arc column in the oil circuit breaker as well as in the air. Current chopping in this circuit breaker mainly depends on the vapor pressure as well as the properties of electron emission in the contact material. So the level of chopping is also affected by the thermal conductivity. When the thermal conductivity is low, then the chopping level will be lower.

It is possible to reduce the level of current at which the current approach to providing sufficient metal vapor by selecting the contact material to reach a very low value, although this is not done frequently as this can adversely affect the dielectric power.

Properties of Vacuum Circuit Breakers:

Compared to other circuit breakers, the insulating medium of the Vacuum Circuit Breaker has a higher capacity for arc destruction. The pressure of a vacuum interrupter is approximately 10-4 torrents. Which involves very few atoms inside the interrupter. The following are the two exceptional properties of this circuit breaker.

This circuit breaker is an excellent dielectric medium compared to other insulating media used in circuit breakers. The Vacuum Circuit Breaker is the best compared to the SF 6 and the Air Circuit Breaker. As this is used for high pressure.

The main current will break at zero after moving the contact into the vacuum and opening a separate arc. Disruption of this arc will increase its dielectric strength by a thousand times compared to other types of breakers. Such properties will make the circuit breaker more efficient, low-cost, and lightweight. It has a longer lifespan compared to other circuit breakers. And it doesn’t need any special maintenance.

The main parts of the vacuum circuit breaker are the vacuum interrupter, terminals, flexible connections, tie bar, support insulator, operating rod, normal operating shift, operating corn, locking cam, spring forming, breaker spring, loading spring, and main link.

Vacuum Circuit Breaker Testing:

Testing of a circuit breaker, in general, is mainly used to test the operation of both separate switching mechanisms as well as the timing of the overall tripping system. Once vacuum interrupters are designed or used in the field. So it mainly consists of three tests used to standardize their function such as contact resistance, high potential survival, and leak-rate testing.

Suggesteed Read: Circuit Breaker Keeps Tripping Without Load | Quick Fix

Difference Between Vacuum Contactor Unit and Vacuum Circuit Breaker:

Vacuum Circuit Breaker means the fault passes through faults like over fault, over current, under current, and short circuit. As the mainline is passed from the fuse to prevent faults in our house. Which provides to avoid fault current. The main differences between a vacuum contactor unit and a vacuum circuit breaker are as follows:

| Vacuum Circuit Breaker | Vacuum Contactor Unit |

| Increases endurance for mechanical | Endurance is very high for mechanical like 1000,000 processes up to 630A |

| This is not used for extremely high-endurance applications. | This is used very frequently for switching operations |

| It is electrically operated | It only conducts electrical |

| It is mechanically latched. As it remains closed on CB system voltage loss. | The vacuum contact is usually unlocked when the system voltage is lost. The vacuum contact is locked when the system returns to the system voltage. |

| This only uses a protective relay. | This uses a protective relay to protect against overload and a fuse to protect against short circuits. |

| Short circuit lat through energy is low | Short circuit lat through energy is low |

| Remote operation is appropriate | Remote operation is appropriate |

| Control power is used to operate CB, protective relays, and space heaters | Control power is used to operate contactors, protective relays, and space heaters |

| It uses a large area | It uses less area |

| It costs a lot more. | The price is moderate. |

| Its maintenance is moderate | Its maintenance is low. |

Advantages of Vacuum Circuit Breaker:

The advantages of the vacuum circuit breaker are as follows:

- There is no danger of fire.

- This increases the safety of the operating employee.

- The vacuum circuit breaker is almost maintenance-free.

- The lifespan of a vacuum circuit breaker is longer.

- The vacuum CB operates quickly so is ideal for fault clearing. VCB is suitable for frequent operations.

- No gas exhaust for atmospheric and noiseless operation.

- VCB explosion can be avoided as opposed to the oil circuit breaker and air blast circuit breaker.

Disadvantages of Vacuum Circuit Breaker:

The disadvantages of the vacuum circuit breaker are as follows:

- The need for high technology arises for the production of vacuum interrupters.

- The main disadvantage of VCB is that it is abnormal at voltages above 38 kV.

- Loss of vacuum due to loss or failure of transport makes the entire barrier useless, and cannot be repaired on-site.

Applications of Vacuum Circuit Breaker:

The application of Vacuum Circuit Breaker is as follows:

- The Vacuum Circuit Breaker is today known as the most reliable current disruption for medium voltage switchgear. It requires minimal maintenance compared to other circuit breakers.

- This technology is suitable for medium voltage but vacuum technology has been developed for high voltage. But that is not commercially possible. Vacuum circuit breakers are also used in metal-clad switchgear and porcelain-housed circuit breakers.

- For less defective interrupt capacity, the cost is lower compared to other interrupting devices.

- Due to the minimum maintenance requirements, these breakers are very suitable for systems that require a voltage of 11 to 33 kV.

Like this post? Share it with your friends!

Suggested Read –