The Eddy current dynamometer is a special device compared to the regular dynamometer. It has very low loss, high efficiency, and is more versatile. In the Eddy current dynamometer, the reason for the loss reduction is that there is no physical contact between the windings and the excitation.

This has many uses due to its small size and combability. In some cases, it is also used as a load to test the performance of internal combustion engines. In today’s article, we will see what Eddy Current Dynamometer is and what its working principle is, and much more about it.

What is the Eddy Current Dynamometer?

The Eddy Current Dynamometer is an electrical energy conversion device whose function is to convert mechanical energy into electrical energy, which works primarily on Faraday’s principle of electromagnetic induction.

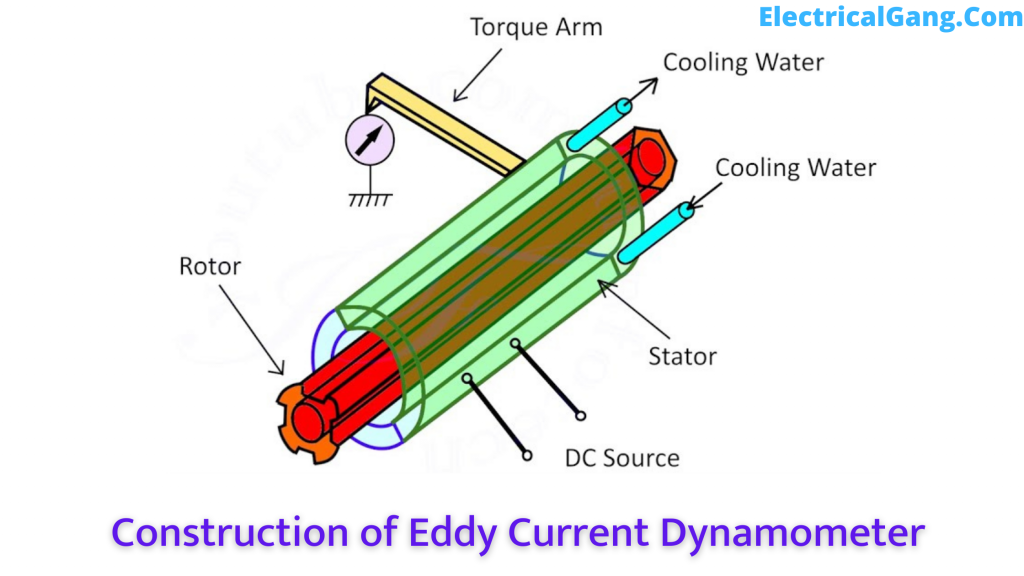

The figure is as follows:

The construction of the Eddy Current Dynamometer is as per the above diagram in which the part of the stator is outside and the winding is properly inserted in the part of the stator slot.

This is excited when the stator winding is powered .and creates a magnetic field. Inside a high-rated machine, the winding is done with 3-phase power. The winding in the stator is made of copper. The stator is made of a magnetic material like cast iron or silicon steel.

The rotating part of the inside of the motor is called the rotor. It is placed between the stator and below the winding. The rotor is placed on its shaft so that it can rotate easily. It is housed in its own slot. 3 phase rotor is also used in the high-rated machine. The part of the rotor is connected to the prime mover. When the prime mover rotates, the device gets mechanical power i.e. energy. DC power is used to stimulate the stator winding.

A rectifier unit is used to get this DC energy in a tall machine. In a large machine, oil is used for cooling and insulation of the stator windings to prevent the stator from getting burnt. The current meter is used to measure the current and torque generated in it as shown in the figure. A pointer is attached to the stator by one hand, which can measure the torque generated in the rotor. Using this, we can calculate the power generated in the machine.

Suggested Read: What Is an Induction Motor | Types of Induction Motor

Eddy Current Dynamometer Working:

The eddy current dynamometer works according to Faraday’s principle of electromagnetic induction as we have stated above. Whenever there is a relative displacement between the mass of the conductor and the magnetic field, an emf is induced on the set of conductors. This emf is called a dynamically induced emf. In the case of dynamometers, when the stator poles are excited by a DC supply that is connected to the stator.

This emf is called dynamically induced emf. In the case of the dynamometer, when the stator poles are excited with a DC supply that is connected to the stator. When this stator is connected to DC power the stator coil is excited and a magnetic field is generated in the coil.

In a 3-phase machine, the stentor coil is excited by 3-phase power. Then, we obtain a 3-phase rotating magnetic field. When the prime mover rotates, the rotor rotates the rotor coil, and the stator contacts the magnetic field.

The thing to keep in mind is that the magnetic field produced by the stator is static in nature. Since the excitation is DC, we get a static magnetic field. This is because in this case the magnetic field is constant and rotates through the position of the conductor. Hence there is a relative displacement between the magnetic field and the conductor.

Suggested Read: Types of Losses in a Transformer | Efficiency Of Transformer

Features of Eddy Current Dynamometer:

It is worth noting here that the Eddy Current Dynamometer is different from the regular Dynamometer because when the rotor of the dynamometer cuts the magnetic field of the stator, an emf is induced on the conductor of the rotor.

The Eddy causes the current to flow in the rotor conductor. The direction of the Eddy current is the opposite of the change in the magnetic flux and is generated in the rotor. The rotor resists the force exerted by the magnetic field but rotates due to the input given by the prime mover.

Since there is no contact between the magnetic field and the conductor, the damage generated is much less than that of a conventional generator. Unlike a regular dynamometer, the Eddy Current Dynamometer has one arm attached to the body of the stator. One meter measures the torque generated in the rotor winding. The speed of the rotor determines the amount of power. Is the same.

Suggested Read: What Are the Losses in DC Machine? | The Definitive Guide

Advantages of Dynamometer:

The advantages of a dynamometer are as follows:

- The design is simple.

- The braking torque is high.

- It is very accurate and stable.

- More efficient than a regular dynamometer due to less friction.

- Can be operated more accurately than a regular dynamometer.

Applications of Dynamometer:

The uses of the dynamometer are as follows:

- Gas turbines.

- Water turbines.

- Automobile transmission parts

- Performance testing of IC engine.

- In the power motor of small rating.

Like this post? Share it with your friends!

Suggested Read –