Hello friends, in today’s article we will see what kind of losses have occurred in the dc machine. And why it can be reduced. As we all know that DC motor is used to convert electric power into mechanical power. Similarly, generators are used to convert mechanical energy into electrical energy.

The input supply in a DC generator is mechanical while the output is electrical. The opposite is true in motors. Thus the input supply is in electrical energy while the output is in mechanical energy. Generally, some power is expended in converting any input power into output power. Which reduces the efficiency of the machine.

The efficiency of the machine can be obtained from the ratio of output power to input power. That is why it is important to know the damage that can be done to a DC machine when designing a rotary machine with high efficiency. In this article, we will look at the various losses that can occur in a DC machine.

Suggested Read: Difference Between AC Motor And DC Motor

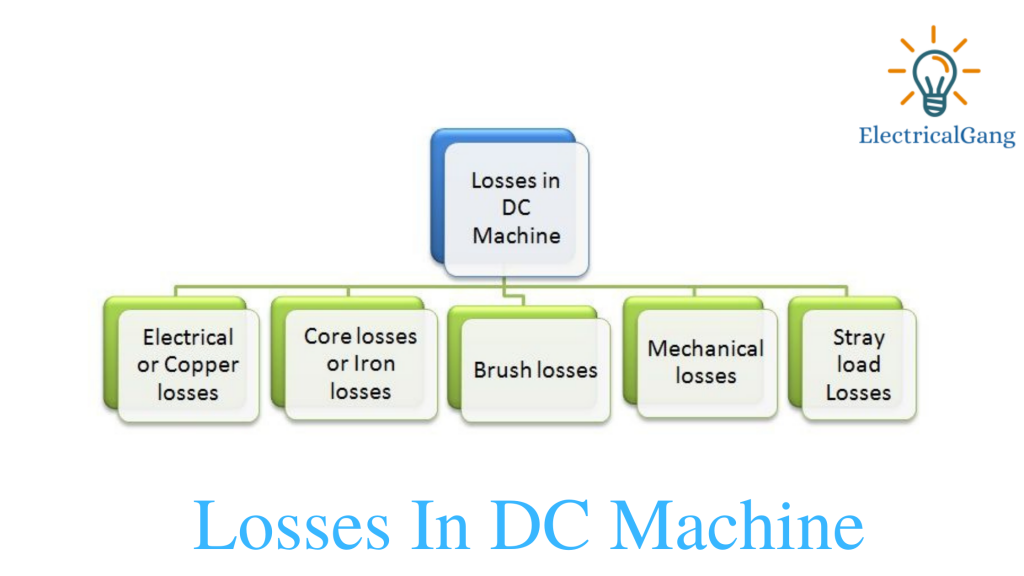

Losses in DC Machine:

There are different types of DC machine damage that are caused by different types. But this loss is caused by heat and its effects. The temperature inside the machine can be increased. So that the life and performance of the machine especially the insulation can be reduced. Therefore, the rating of a DC machine can be directly affected by different losses.

Several types of damage to a DC machine are discussed below:

Types Of Losses in DC Machine:

The losses in the DC machine are as follows:

| Sr. No. | Types of Losses in DC Machine |

| #1. | Electrical or Copper Losses in DC Machine |

| #2. | Magnetic Losses or Core Losses or Iron Losses |

| #3. | Hysteresis Losses |

| #4. | Eddy Current Loss |

| #5. | Brush Losses |

| #6. | Mechanical Losses |

| #7. | Stray Losses |

#1. Electrical or Copper Losses in DC Machine:

Electrical or copper losses occur in stator windings and armature windings in DC machines. This type of loss includes different types of loss. Such as copper loss armature damage caused by contact with a copper brush.

Here, armature copper loss can be obtained as Ia2Ra2.

Where

‘Ia’ is the armature current.

“Ra ‘is the resistance of the armature.

This type of loss is 30% to 40% of the full load loss. These losses are variable and depend mainly on the amount of DC machine load. Filed copper loss can be recovered as If2Rf

Where are you

(‘If’ field is current while the Rf field is resistance)

In a separately injured field, the copper loss of the field is practically stable and it donates 20% to 30% of the full-load loss. Resistance to brush contact contributes to the copper loss. Typically, such damage falls under armature copper loss.

Suggested More: What is an Ideal Transformer? | The Definitive Guide

#2. Magnetic Losses Core Losses or Iron Losses:

Alternative names for this damage are iron damage or major damage. This type of damage can occur in the armor core and teeth wherever the flux can be changed. These losses include two major losses, such as hysteresis and eddy current loss.

#3. Hysteresis Losses:

This loss in the armature core is due to reverse magnetism.

Ph = ȠB1.6maxfV watts

Ph = 1B1.6maxfV watt.

Here, ‘Bmax’ is the highest flux density value within the core.

‘V’ is the armature core volume.

‘F’ is the reverse magnetism frequency.

‘Yst’ is a co-efficient of hysteria.

Hysteresis loss also occurs between the teeth and the armature core in the dc machine. This loss can be minimized by the silicone core. This material has a low hysteresis coefficient.

Suggested Read: Types of Losses in a Transformer | Efficiency of Transformer

#4. Eddy Current Loss:

Once the armature core is converted into a magnetic field of the pole and cut off the magnetic flux. Thus, the emf can be induced into the core body based on the law of electromagnetic induction. The inductive e.m.f can be used to set the current inside the armature core body that is why it is called eddy current.

And the loss of power due to current flow is called heel current loss. This can be achieved as a loss The heel is given by the current loss

Heel current loss = KeB2maxf2t2V watts

From the above equation

The ‘K’ is constant, depending on the basic resistance of the unit’s use and the system.

‘Bmax’ is the maximum flux density within wb/m2.

‘T’ thickness m is the lamination thickness.

‘V’ is the main volume in ‘m3’.

This damage can be minimized by making an armature core with thin laminated stamps. Therefore the lamination thickness used in the armor core can be from 0.35 mm to 0.5 mm.

#5. Brush Losses:

This type of damage can occur between a carbon brush and a commutator. This is the power loss at the end of the brush contact in a DC machine. This can be expressed as

PBD = VBD * IA

Where

‘PBD’ has the disadvantage of brush drop.

‘VBD’ is the voltage drop of the brush.

‘IA’ is the armature current.

#6. Mechanical Losses:

Mechanical damage can occur due to the impact of machines. This loss can be divided into two main parts, one bearing friction and the other windage. This damage can occur to moving parts inside a DC machine. The air in a DC machine is also known as windage loss.

Windage loss is extremely small and can be caused by friction in the bearing. This damage is also known as mechanical damage. These damages include brush friction and bearing, Windies lose otherwise air fiction rotary armature. In the full-load loss, this loss is about 10% – 20%.

#7. Stray Losses:

These are mixed types of losses and there are factors to consider in this loss. Distortion of flow due to armature reaction The short circuit inside the coil.

Due to the AD current inside the conductor, there is an excess copper loss. Such losses cannot be determined. Therefore, it is necessary to allocate the logical value of this loss. In most machines, this loss is assumed to be 1%.

Suggested Read: Advantages of High Transmission Voltage

How to reduce the loss lost in a DC machine?

Damage to DC machines is mainly caused by three different sources such as resistive, magnetic, and switching. To reduce magnetic and hysteresis damage, cover the magnetic core to prevent eddy currents.

Resistant damage can be minimized depending on the precautionary design to fill the cross-sectional area with wire, the size of the wire, and the thickness of the insulation are significant.

Most Commonly Asked Questions:

Which losses occur in a DC machine?

The losses in the DC machine are as follows:

| Sr. No. | Types of Losses in DC Machine |

| #1. | Electrical or Copper Losses in DC Machine |

| #2. | Magnetic Losses or Core Losses or Iron Losses |

| #3. | Hysteresis Losses |

| #4. | Eddy Current Loss |

| #5. | Brush Losses |

| #6. | Mechanical Losses |

| #7. | Stray Losses |

What are the losses in a generator?

Loss from such a source is known as copper loss. Such power loss is equal to the power lost due to heating the wire used in the generation. Another significant loss in the generator is known as hysteresis loss. Hysteresis is sometimes defined as molecular friction due to the changing magnetic field.

What are Eddy’s current losses?

The eddy current loss is the conductor I2R loss produced by the rotation of the currents induced in response to the AC current connection, which flows against the internal resistance of the core.

How do dc machines reduce losses?

Damage to DC machines is mainly caused by three different sources such as resistive, magnetic, and switching. To reduce magnetic and hysteresis damage, cover the magnetic core to prevent eddy currents.

Like this post? Share it with your friends!

Suggested Read –

- Highway/Street Light Names And Functions

- Submersible Pump | Types of Submersible Pump

- What is a Paper Capacitor? | The Definitive Guide

- What Is a Galvanometer | Construction of Galvanometer

- What is Hot Wire Instrument | Construction & Working of Hot Wire Instrument

Final Thoughts :

Thus all this is about an overview of the different types of losses in a DC machine. The DC machine is mainly divided into five categories like Electric / Copper, Magnetic/Core/Iron, Brush, Mechanical, and Stray.

Very Informative Post. Thanks for sharing the information. Keep Posting.

Thank you so much