strain gauge The first discovery was made by Edward E. Simmons and Arthur C. Rouge in 1938. This discovery led to significant measurements of stress in various formats. A strain gauge is a type of sensor that can be used to measure the stress of anything and in a variety of applications.

It is an important and essential geotechnical tool that helps in determining the stress in the area of structures like tunnels, underground cavities, buildings, bridges, concrete, masonry dams, embedded in clay/concrete, etc.

In this article, we will talk about what is strain gauge and get detailed information about strain gauge including working principles, characteristics, and applications.

Suggested Read: What Is DC Generator? | The Definitive Guide

What is a Strain Gauge?

A stress gauge is one of the stress gauges used in the field of geotechnical engineering to measure stress on different structures. A strain Gauge has a register that is used to measure the stress of any object. The time when an external force is applied to anything. Due to this force, a change in the shape of the object is recorded. Both shrink or expand in shape are called stresses. Which is measured with the help of this Strain Gauge.

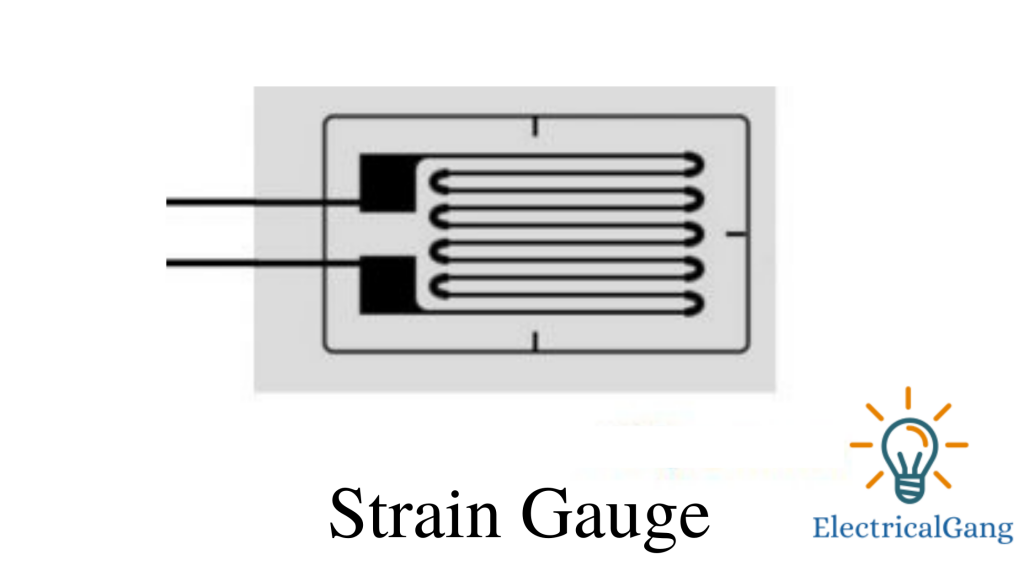

When an object loses its original shape, it lengthens or shrinks. Or become smaller or become wider. This results in a change in its end-to-end resistance. The strain gauge is sensitive to small changes in the geometry of the object. The amount of refreshing stress can be calculated to measure the change in resistance of the object. The change value of resistance is usually very low and to understand this a small change strain gauge has a long thin metal belt.

Which has a long thin metal strip with zigzag pattern adjustment on non-conductive material as shown below:

To increase the small amount of stress in the set of parallel lines and to measure the exact result. Strain gauze is glued to the tool with the help of any adhesive material.

Strain Gauge Bridge Circuit:

The strain Gauge Bridge Circuit represents the stress measured by the degree of anomaly. And a voltmeter in the middle of the bridge is used to provide the perfect measure of this imbalance.

In this circuit, the R1 and R3are ratio arms are identical to each other, and R2 has the same value as the strain gauge resistance of the rheostat arm. The time bridge is balanced when the time gauge is uncontrollable, and the voltmeter shows zero value.

As the resistance of the strain gauge changes, the bridge becomes unbalanced and a signal is generated on the voltmeter. The output voltage from the bridge can be further increased by a differential amplifier.

Gauge Factor of Strain Gauge:

Gauge factor G.F. has given

GF = (∆R⁄RG) /ε

Where,

‘ΔR’ is a change in resistance due to stress.

‘RG’ is the resistance of the unaltered gauge.

‘ε’ is stress.

The gauge factor of ordinary metallic foils is about 2. The output sensor voltage of the Whiston Bridge is S.V. Provided by,

SV = EV (GF.ε) / 4

Where EV is the bridge excitation voltage

Suggested Read: What is Transducer | Types of Transducer | Application of Transducer

Strain Gauge Working:

The function of the strain gauge depends entirely on the resistance of the object/conductor. When an object is stretched to the limit of its elasticity and does not break or buckle permanently, it becomes thinner and longer, resulting in higher electrical resistance.

If anything is compressed and does not become abnormal. But, if expanded and shortened, the result is a decrease in electrical resistance. The values obtained after measuring Gauge’s electrical resistance help to understand the stress-induced magnitude.

The exciting voltage is applied to the input terminals of the Gauges network while the output is read at the output terminals. These are usually attached to the load and are likely to remain stable for long periods, sometimes decades.

The glue used for the gauge depends on the duration of the measurement system. Cyanoacrylate glue is suitable for short-term measurements and epoxy glue for long-term measurements.

Working Principle of Strain Gauge:

As we all know that resistance directly depends on the length of the conductor and the cross-sectional area,

Which is given by R = L/A.

Where,

‘R’ = resistance

‘L’ = is the length

‘A’ = is the cross-sectional area

Clearly, the length of the conductor varies with the change in the shape and size of the conductor,

Eventually, the cross-sectional area and resistance change.

Any common gauge has a conductor strip that is long and thin, and a zig-zag design of parallel lines is arranged. The purpose of this zig-zag configuration is to elaborate on a small amount of tension between parallel lines with great precision. Stress is expressed as the resistance of an object.

Suggested Read: Types of Electrical Insulator in Transmission Lines

Strain Gauge Rosettes:

Strain gauge rosettes are two or more gauges located close together in a rosette-like structure to measure the number of components to evaluate the specific stress on the surface. The picture is shown in the figure below.

Characteristics of Strain Gauges:

Some of the important characteristics of a strain gauge are as follows:

- This is no longer appropriate with certain precautions.

- They provide precise values with changes in temperature and other factors.

- It is easy to build with simple components.

- Which is easy to maintain and has a long lifespan.

- This is fully included to prevent damage such as handling and installation.

- The strain gauge is perfect for long-term installation. However, they require certain precautions when installing.

- The remote digital readout is also possible for strain gauges.

Suggested Read: Optical Sensor Basics | Types of Optical Sensor

Applications of Strain Gauge:

Strain gauges are widely used in the field of geotechnical surveillance for continuous inspection of structures, demos, tunnels, and buildings.

To avoid accidents in a timely manner. The application of strain gauge includes.

- Aerospace.

- Nuclear power plants.

- Rail supervision.

- Cable bridge.

Most Commonly Asked Questions:

What is the principle of strain gauge?

Strain gauge works on the principle of electrical conductivity and its dependence on the geometry of the conductor. Whenever the conductor is stretched to the limit of its elasticity it does not break but becomes narrower and longer.

What is the construction of the strain gauge?

Strain gauges are made by combining an electric insulation base and gauge leads to a grid made of fine electric resistance wire or photographically attach metallic resistance foil.

What Is a Strain Gauge?

A stress gauge is one of the stress gauges used in the field of geotechnical engineering to measure stress on different structures. A strain Gauge has a register that is used to measure the stress of any object. The time when an external force is applied to anything. Due to this force, a change in the shape of the object is recorded. Both shrink or expand in shape are called stresses. Which is measured with the help of this Strain Gauge.

What is the application of a Strain Gauge?

The application of Strain Gauge is as follows:

- Aerospace.

- Nuclear power plants.

- Rail supervision.

- Cable bridge.

Like this post? Share it with your friends!

Suggested Read –

- What is a Signal Isolator? | A Complete Guide

- Highway/Street Light Names And Functions

- How to Fix YouTube TV Freezing Issues in Easy Steps

- How to Solve LG Content Store Not Working Problem?

- What is a Phototransistor | Construction of Phototransistor

- What is a Single Phase Transformer | Construction of Single Phase Transformer