Hello friends, in today’s article we will talk about how many types of electric poles there are. We use different types of poles for overhead transmission, also known as line support.

In general, this pole must have the following properties:

- To withstand the weight of wind and heavy conductors i.e. its mechanical strength should be strong.

- Its weight should be as low as possible without reducing its mechanical strength.

- The lifespan of the pole should belong.

- The lower the price the lower the maintenance required.

- Easy access to overhead line maintenance.

Types of Electric Pole

The following line support is used for the transmission and distribution of electric power

| Sr. No. | Types of Electric Pole |

| #1. | Wooden Electric Pole |

| #2. | Steel Tubular Electric Pole |

| #3. | Concrete Electric Pole |

| #4. | Lattice Steel Structure |

| #5. | Rail Electric Pole |

Wooden Electric Pole

Many years ago an electric pole made of wood was used which was used in 400-volt and 230-volt low-tension lines. The cost of a pole made of wood is less than that of other poles. In other poles, the cost of a foundation is more which can be said to be equal to that of a wood pole. Can serve for a long time.

Due to all these features, it was used extensively. Shawl wood was commonly used to manufacture electric poles, as it was considered the best for this purpose. The weight of shawl wood is 815 kg per cubic meter. Given the current situation and the consequences of global warming, the use of wooden poles has been discontinued to save the forest.

The wooden poles are classified into three sections keeping in view the weight of the overhead line conductor.

- Shaal, Masua wood is used for breakdown force above 850 kg/cm2.

- Tik, Seishun, and Garjan wood is used for breakdown force between 630 kg/cm2 and 850 kg/cm2.

- Chir, Debdaru, and Arjun wood are used for breakdown force between 450 kg/cm2 and 630 kg/cm2.

The wood used to make the pole should not have any defects. It is possible to use straight wood for the pole. But it is a little harder so it can be used even if it is slightly curved. This pole can also be made by combining two short lengths of wood if possible.

Suggested Read: The Best Pole Changing Method | Speed Control for Induction Motor

Treatment of Wooden Pole

First of all, you have to make sure that the wood you select for the pole is properly dried. Mushrooms and locusts cause a lot of damage to the wood. Also, there is a significant loss of wood due to moisture and heat.

Damage like mushrooms and termites is found in the base of the pole and at ground level. Pole wood must be properly chemically treated to prevent this defect. Tar mixed with crepe oil or copper chrome arsenic is used for proper maintenance of the pole. This is followed by an escalation treatment.

In the escape treatment, the pole is kept in a cylindrical airtight closed tank. The ends of the pole in the tank are completely immersed in copper chrome arsenic chemicals. 100 kg per square meter pressure is kept inside the tank for at least one hour.

Due to this high pressure, the chemical is easily absorbed into each hole of the wood so that the pole can withstand moisture and termites for a long time. If the pole is not treated properly for some inexplicable reason and if the pole has to be raised, coats of crease oil are applied on its entire surface before applying.

Bituminous Creojet Oil, applied on the ground as well as 50 cm from the ground. Or used up to 20 inches. If this is not possible, it is imperative to apply at least tar to such a surface of the pole. If none of the treatments outlined above are possible, the skin can be burned up to 2 meters below and outside to protect the pollen from moisture and termites.

The top of the pole is cut into a suitable cone shape so that rain or any other cause does not fill the top of the pole. The pole is then grooved by making a hole at the appropriate distance so that the cross arm can be fixed to carry the conductor on it.

The distance between the two holes for the cross-arm should be at least 200 mm or 8 inches. All these holes and groove poles must be treated first. Once the pole is treated, such holes and grooves should be avoided. But if the inexplicable reason is to make a hole or groove in it, then it is necessary to apply creosote oil or bitumen on the grooves.

Suggested Read: What Is Stator? | Construction of Stator

Steel Tubular Electric Pole

Steel poles have a higher load-bearing capacity than wood poles and RCC poles. If properly maintained, the life of these poles is extended. But the demand for this poll has gone down due to its high cost.

This pole is used for systems below 400/230 volts and medium current. We use these poles for 11 kV HT. Also, do it in Line. We sometimes use these poles in a high voltage like voltage 33 kV system.

Types of Tubular Poles

The Tubular Electric Pole is divided into two sections as follows:

| Sr. No. | Types of Tubular Poles |

| #1. | Stepped Pole |

| #2. | Swaged Pole |

One is called ISTP and the other is called ISWP. The ends of both poles can be inserted into a tube or inserted into several tubes and then welded together properly. Tubular Electric Pole should be straight clean and corrosion free and defect-free.

These poles come in different sizes to hold different loads and capacities. The Pole gauge for the high-tension line is more than the low-tension line. The pole needs to be coated with bitumen from both inside and outside.

The rest of the length of the pole is colored with red oxide. A 14 mm diameter hole is made 300 mm above the ground to give the pole proper earthing. To protect the pole from rainwater, it is given a pole cap at the top.

Suggested Read: What is Armature Winding | Types of Armature Winding

Concrete Electric Pole

There are two main types of Concrete Electric poles which are as follows.

- P.C.C. Poles.

- R.C.C. Poles.

#1. P.C.C. Poles

The full name of PCC is Plain cement concrete and currently, the PCC pole is widely used. This pole is mostly used in 11 kV and 400/230-volt systems. Apart from this, this pole is used as high as 33KV and is also used for the tension lines. The strength of the PCC pole is higher than that of the wood pole and less than that of the steel pole.

Such poles are more expensive than wood and cheaper than steel poles. The life span of this pole is long. And maintenance costs are equal to no. The disadvantages of PCC poles are that they weigh more than wood and steel poles and are breakable.

#2. R.C.C. Poles

The full name of RCC is Reinforced Cement Concrete. As it is named, it is made of cement concrete. To increase its durability, iron rods are used inside it. For earthing, a 25 mm size 3 mm copper strip is used or a hollow channel is placed in the pole for laying the earthing wire.

To fix various fittings on the pole as required, we make holes of 20 mm diameter when laying gravel. The width of this pole is greater than the bottom of the top. At the same time, the cross-section of the PCC pole is rectangular, not square.

It is divided into 11 categories based on load capacity and pole height.

| Classification of Pole | Height in Mtr. | Excavation of Footing Deftness in Mtr. | Maximum LateralLoad in Kg.2 |

| 1 | 16.5 – 17 | 2.4 | 3000 |

| 2 | 16.5 – 17 | 2.4 | 2300 |

| 3 | 16.5 – 17 | 2.4 | 1800 |

| 4 | 16.5 – 17 | 2.4 | 1400 |

| 5 | 14.5 – 16 | 2.3 | 1100 |

| 6 | 11.5 – 12 | 2 | 1000 |

| 7 | 11.5 – 12 | 2 | 800 |

| 8 | 11.5 – 12 | 2 | 700 |

| 9 | 9.5 – 11 | 1.8 | 450 |

| 10 | 8 – 9.0 | 1.5 | 300 |

| 11 | 6 – 7.5 | 1.2 | 200 |

Suggested Read: What Is Motor Winding | Types Of Motor Winding | Motor Winding Calculation

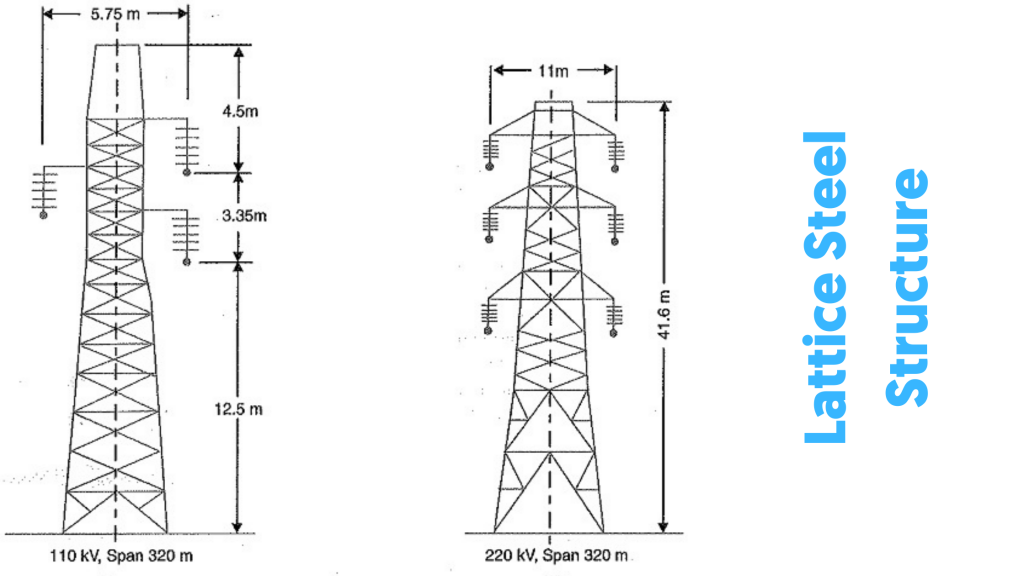

Lattice Steel Structure

Normally we use wood steel and RCC poles for an 11KV power supply but when it comes to transmitting more power than that, we have to use Lattice Steel Structure. The peculiarity of this structure is that its mechanical strength is higher than the rest of the pole, it has a long life, can withstand any harsh climate, and is excellent for long spans.

The risk of service interruption due to broken or punctured insulation over a long period is significantly reduced. It is imperative to provide airtight to such a large pole as it reduces the electrical difficulties in difficult situations as acts like every tower conductor constructed by it.

As shown in the figure we can see that it uses a single circuit however we can also convert this to a double-circuit by spending moderately or a little more. The main advantage of having a double circuit is that even if there is a breakdown in one circuit, the power supply continues through the other circuit.

Suggested Read: What Is DC Generator? | The Definitive Guide

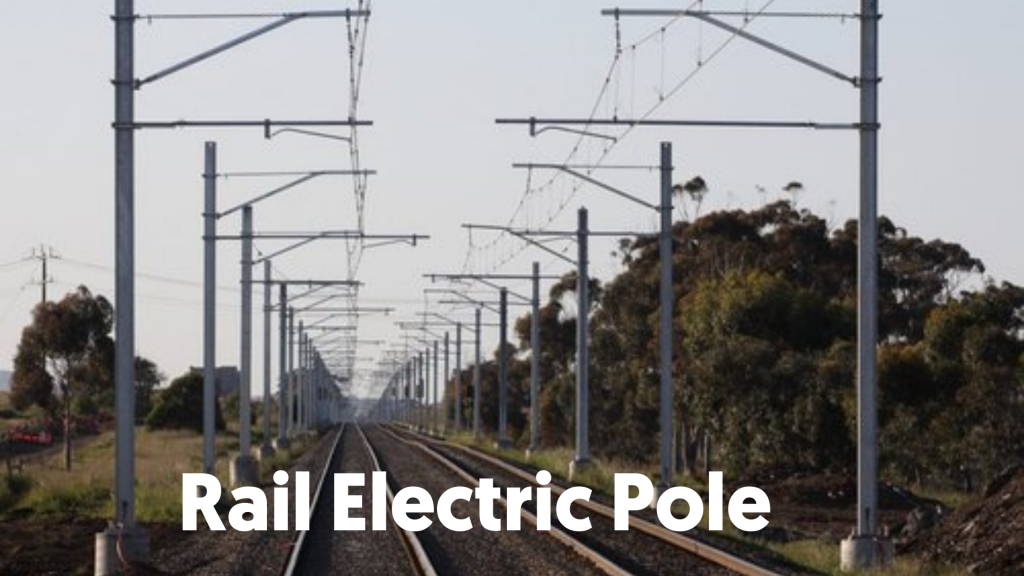

Rail Electric Pole

Rail Electric Pole has more strength but their cost is also equal to their strength. And this pole also has more weight as it can withstand any tough weather. For the 400/230 volt line, this pole is not used but in the 11 kV and 33 kV systems, we use this in the railway poles.

The rail poles used in overhead lines are usually of four sizes.

- 30 kg per meter.

- 37 kg per meter.

- 45 kg per meter.

- 52 kg per meter.

Usually, a 45 kg per meter railway pole is used in the 11kv line. Usually, the height of the railway pole ranges from 9 meters to 13 meters. At least one coat of red oxide is applied to the pole before the work is done.

If we apply a tar coat on the bottom part up to the height above the ground, the durability of the pole increases. The vertical load-bearing capacity of the railway pole is also greater than the horizontal load-bearing capacity.

Like this post? Could you share it with your friends?

Suggested Read –