Hello friends, in today’s article, we will look at the types of electrical wiring and discuss in detail the different wiring methods.

What is Electrical Wiring?

Electrical wiring is nothing but the process of combining all the lights, fans, televisions, and motors running in our house, arranging the wire properly, and bringing it to the distribution board, which is known as electrical wiring.

Methods of Electrical Wiring Systems w.r.t Taking Connection:

Wiring is a system in which we can easily operate all the appliances in the house from the meter through the distribution system. This wiring can be done in two ways.

The two methods of wiring system are as follows:

- Joint Box system or Tee system.

- Loop in the system.

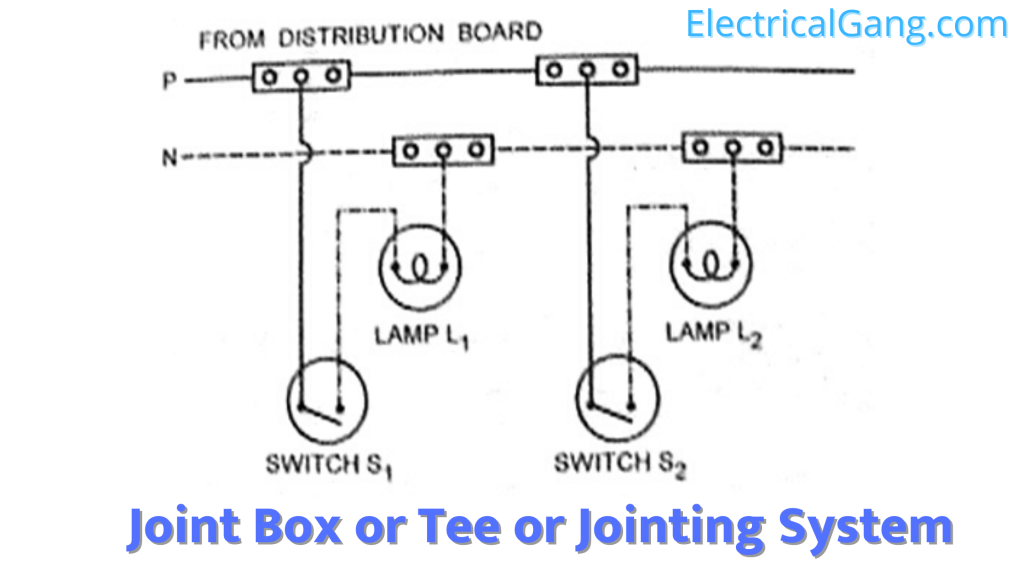

#1. Joint Box or Tee or Jointing System:

To operate any of these devices under the Tee system or joint box system, we take it jointly from the middle of the wire and give it to the tool or device that we cut into the wire inside the cut box. Therefore, less wire is used in this system.

This system does not require a large amount of wire, so the cost of this system is relatively low. But the money that is saved is used to buy a box, so the equation of this matter of money becomes the same. This system is suitable for temporary installations and is inexpensive.

Suggested Read: What Is Electrical Grounding? | The Definitive Guide

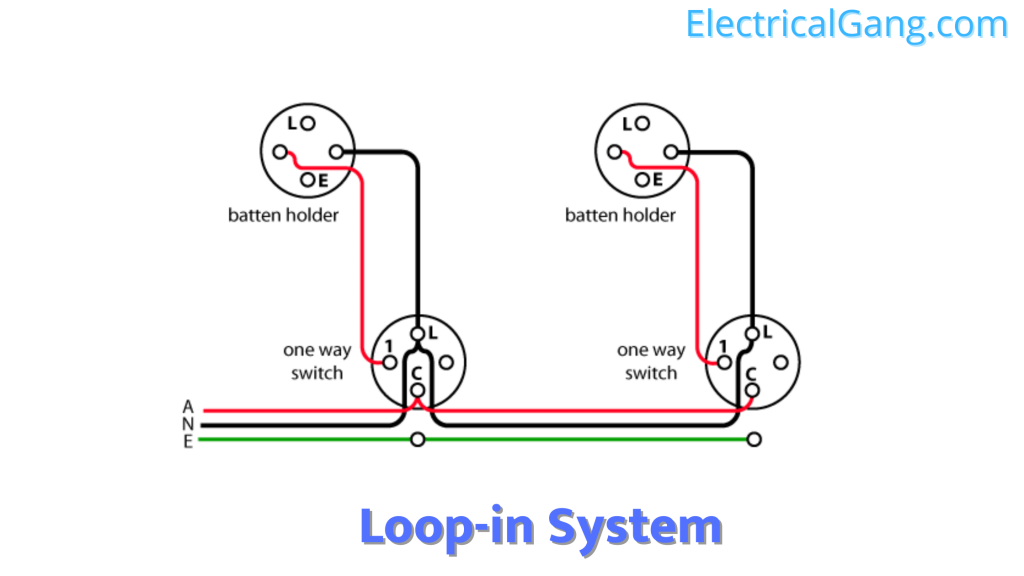

#2. Loop-in the System:

This system is widely used in the market. In this system, lights, fans, and other devices are connected in parallel. So that the power received by this system is received by each device individually. When new power is required on a light or switch, it is connected from board to board without giving any cut in the wire as opposed to the joint box system.

This one circuit is carried from board to board through a series. Until the last board of this series arrives, in this system, the phase or line conductor is looped inside the switchboard or box. In any condition, these wires should not be separated from each other; otherwise, the front circuit will open and will not work.

Advantages of the Loop-In Method of Wiring:

The advantages of the Loop-In Method are as follows:

- It is easy to locate the fault. Because the circuit of the wire is obtained from board to board.

- Combined boxes are no longer needed to save money.

- In an in-loop system, no joint of wire is pressed into concealment.

Disadvantages of the Loop-In Method of Wiring:

The disadvantages of the Loop-In Method are as follows:

- The longer the wire in this system, the greater the voltage drop across the line.

- Looping usually becomes difficult in switches and lamp holders.

Types of Electrical Wiring Systems:

The types of internal wiring used in the market are as follows:

| Sr. No. | Types of Electrical Wiring Systems |

| #1. | Cleat Wiring |

| #2. | Lead Sheathed or Metal-Sheathed Wiring |

| #3. | Wooden Casing and Capping Wiring |

| #4. | Batten Wiring (CTS or TRS) |

| #5. | Conduit Wiring |

The types of wiring used depend on the pipe installation.

- Surface or Open Conduit Type.

- Recessed or Concealed or Underground Type Conduit.

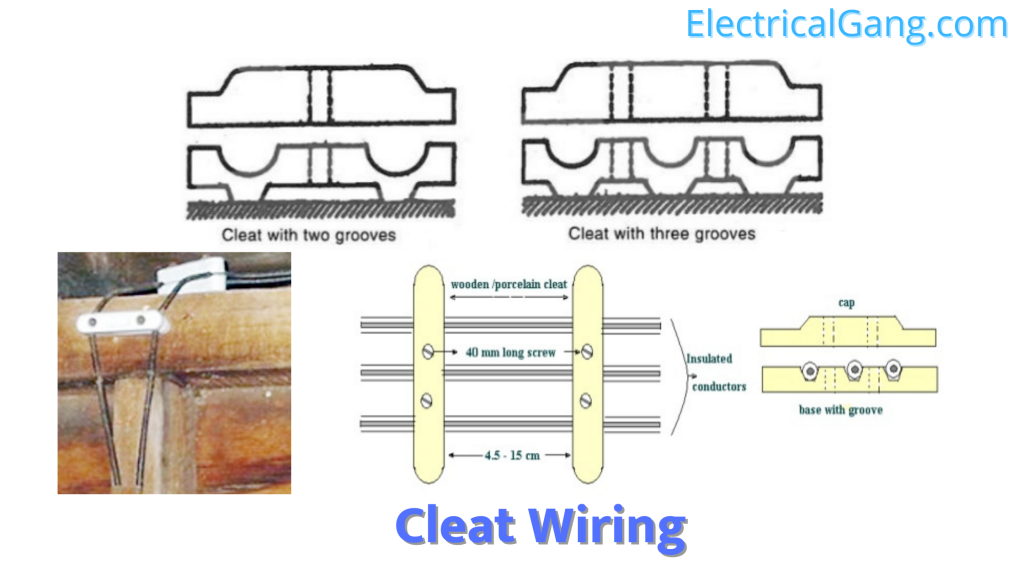

#1. Cleat Wiring:

This wiring system uses VIR (Vulcanised Indian Rubber) or PVC (Polyvinyl chloride) wire. This wire is braided and compounded on walls or ceilings using porcelain clays.

This wire can be weatherproof. This is usually configured when wiring. At present, this wiring is not used at home. This is because it is temporary wiring. It is used especially on temporary military campuses or festival-related pavilions.

Advantages of Cleat Wiring:

The benefits of Cleat Wiring are as follows:

- The Cleat Wiring system is simple and easy to install.

- The wiring underneath is obviously in the open air. So, if there is a defect in a wire or cable, it can be repaired easily and quickly.

- Improvements in the wiring can be easily added, e.g., alteration and addition.

- Since the work is in progress, it is used under construction for army camps.

Disadvantages of Cleat Wiring:

The disadvantages of Cleat Wiring are as follows:

- This wiring is not used permanently as, over time, it becomes loose between the two clamps, i.e., sag falls.

- This is used at low temperatures only at 250/440 volts.

- Looks bad compared to other wiring in appearance.

- Since this wiring is exposed to air, it can be damaged by moisture, sunlight, rain chemicals, and acidic effect cables.

- The possibility of electric shock and fire remains.

- Not long life.

- This is not used in the space of importance and sensitive space.

Suggested Read: What is 2 Way Switch | 2 Way Switch Wiring

#2. Lead Sheathed or Metal-Sheathed Wiring:

This type of wiring allows the conductor, which is insulated with VIR. It has about 95% lead aluminum alloy in the outer casing, which protects the metal casing from moisture, mechanical damage, and atmospheric corrosion.

The entire lead covering is electrically seamless and is attached to the ground at the point of entry to protect against electrolytic action due to leakage and to provide safety if the casing comes alive.

The cable is run on a wooden bat and fixed by link clips, just like the TRS wiring.

#3. Wooden Casing and Capping Wiring:

Casing capping This wiring has been used extensively in the past, but since the introduction of concealed wiring, the demand for this has been very low. The cables used in this system are VIR (Vulcanised Indian Rubber) or PVC (Polyvinyl chloride) wire.

The cable is carried by enclosures of the wooden or plastic casing. The cover is made of wood strips or plastic. The parallel groove is cut in the direction of length so that the VIR cable can be easily accommodated. Grooves were made to separate the anti-polarity. Capping (also made of wood or plastic) is used to install and fit wires and cables into the casing.

Advantages of Casing Capping Wiring:

The advantages of Casing Capping Wiring are as follows:

- It is a powerful and long-lasting wiring method.

- Inexpensive and easy to install the system.

- Customization in wiring can be done easily.

- Being fixed in the cover protects it from smoke, dust, rain, steam, etc.

- Having a cover on the wire does not create a shock-like condition.

- This can be easily repaired if the phase and neutral slots are separated.

Disadvantages of Casing Capping Wiring:

The disadvantages of casing capping wiring are as follows:

- Maintenance becomes more expensive.

- Not suitable for weather conditions with high humidity and acidic conditions.

- The risk of fire remains high.

- Content is not easily found in the contemporary Part.

- Locusts damage wood coverings and capping.

Suggested Read: What is a Thermocouple | Construction of Thermocouple

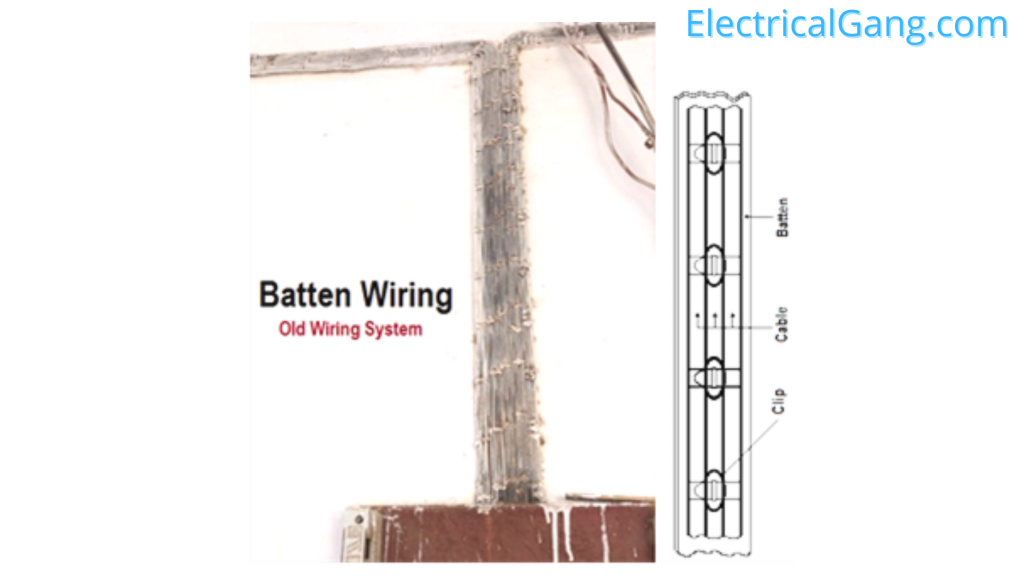

#4. Batten Wiring (CTS or TRS):

This type of wiring uses a single-core, double-core, or round, oval cable with a three-core TRS cable. For this, a single-core cable is preferred. TRS cable is waterproof, chemical proof, and steam proof but can be affected by lubricating oil. The TRS cable is fixed to the strong teak wood with a thickness of at least 10 mm.

The cable is placed on the wooden buttons via a tinned brass link clip (buckle clip), which is already fixed to the baton with brass pins and is 10 cm for horizontal runs and 15 cm for vertical runs. Occurs at intervals.

Advantages of Batten Wiring:

The Benefits of Batten Wiring are as follows:

- This is easy to maintain.

- Modifications to this wiring can be made easily.

- The life of this wiring is long.

- Looks good in appearance.

- Costs are lower compared to other wiring.

- The probability of current leakage remains low.

Disadvantages of Batten Wiring:

The disadvantages of Batten Wiring are as follows:

- There is a risk of fire.

- Due to moisture and chemical effects, it is not suitable for outdoor use.

- Only suitable for use below 250V.

- Heavy wire is not used in this wiring.

- More cables and wires are needed.

#5. Conduit Wiring:

There are two main types of Conduit Wiring, which are as follows:

- Surface Conduit Wiring.

- Concealed Conduit Wiring.

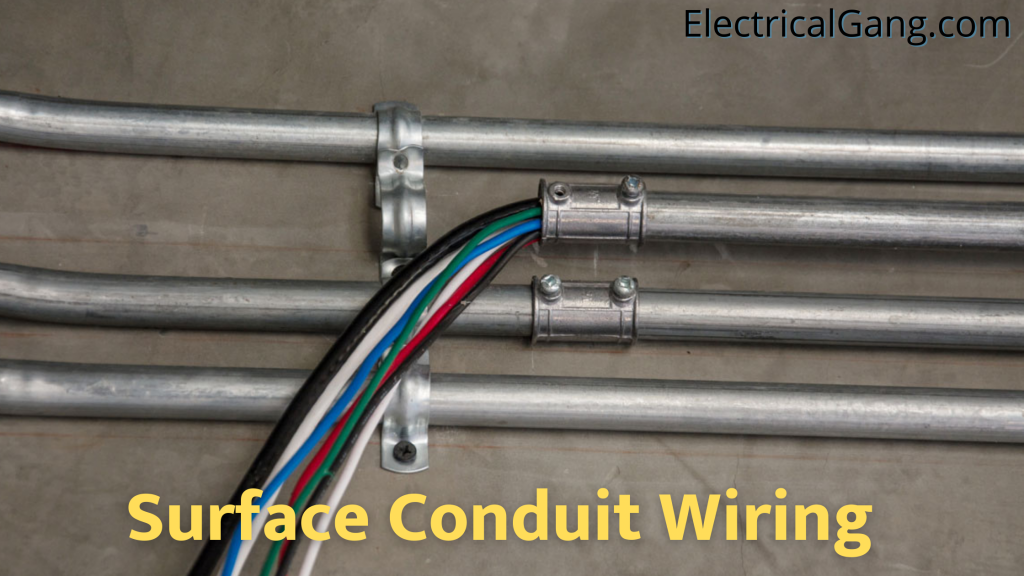

#5.1 Surface Conduit Wiring:

This wiring is done on the outside of the wall, obviously. Such wiring is known as Surface Conduit Wiring. This is done by making a hole in the wall at equal distances and fixing it with the help of a GI clamp. And by pulling the wire through this pipe, it is given to the board and light, fan, or another consumer device.

#5.2 Concealed Conduit Wiring:

A plastic or metal pipe is concealed inside the plaster by drilling a hole in the wall under this wiring. This wiring is called Concealed Conduit Wiring. Says Conduit Wiring. These wiring mouths are widely used nowadays.

In this wiring, the pipe that is pressed inside the plaster should be continuous, and there should be no puncture or blockage. If a steel or other metal pipe is used, it is necessary to give it some distance earthing. But especially when it comes to the house, most of the PVC pipe is used.

Doing this wiring protects against rodents and rodents. Wire cutting can easily get rid of such a problem. That is why this wiring is more convenient and popular for homes or offices.

Advantages of Concealed Conduit Wiring:

The benefits of Concealed Conduit Wiring are as follows:

- Looks good in appearance compared to other wiring.

- Wire insulation is not damaged in any way.

- The lifespan of this wiring is long.

- Is shockproof.

- Safe compared to another wiring.

- There is no risk of fire or mechanical wear and tear.

Disadvantages of Concealed Conduit Wiring:

The disadvantages of Concealed Conduit Wiring are as follows:

- The cost of this remains high.

- Customization is not easy.

- Locating faults is not easy.

- Installation is difficult.

Suggested Read: Why My Fios Remote Not Working? | Here’s How to Fix It

Types of Conduits:

There are two types of conduits used in concealed wiring and open wiring, which are as follows:

- Metallic Conduit.

- Non-metallic Conduit.

#1. Metallic Conduit:

Metallic Conduit is made of steel and is very strong and expensive.

The Metallic Conduit is divided into two parts as follows:

Class A Duct: Low gauge duct (thin layer steel sheet duct).

Class B Duct: high gauge duct (a thick sheet of steel duct).

#2. Non-metallic Conduit:

Non-metallic Conduit It is said that no metal of any kind is used in its construction, like PVC pipe, whose construction does not use any metal.

Size of Conduit:

Normal conduit pipes are available in different sizes, 13, 16.2, 18.75, 20, 25, 37, 50, and 63 mm (diameter) or 1/2, 5/8, 3/4, 1, 1.25, 1.5, and in diameter. 2 inches.

Comparison Between Different Wiring Systems:

| Feature | Cleat Wiring | Casing Capping Wiring | Batten Wiring | Conduit Wiring |

| Life | Short | Fairy Long | Long | Very Long |

| Cost | Low | Medium | Medium | Highest |

| Mechanical Protection | None | Fair | None | Very Good |

| Possibility of Fire | Nil | Good | Good | Nil |

| Installation | Very Easy | Difficult | Easy | Difficult |

| Inspection | Easy | Easy | Easy | Difficult |

| Repair | Easy | Slightly Difficult | Easy | Difficult |

| Popularity | Nil | Fair | Nil | Very High |

| Type of Skilled | Semi-Skilled | Highly Skilled | Semi-Skilled | Highly Skilled |

House Wiring Types:

| Sr. No. | House Wiring Types |

| #1. | Cleat Wiring |

| #2. | Lead Sheathed or Metal-Sheathed Wiring |

| #3. | Wooden Casing and Capping Wiring |

| #4. | Batten Wiring (CTS or TRS) |

| #5. | Conduit Wiring |

Types of Electrical Installation:

There are 3 types of installations found in the market. These are as follows:

- Residential installations.

- Commercial installations.

- Vehicular installations.

Types of Domestic Wiring:

| Sr. No. | Types of Domestic Wiring |

| #1. | Cleat Wiring |

| #2. | Lead Sheathed or Metal-Sheathed Wiring |

| #3. | Wooden Casing and Capping Wiring |

| #4. | Batten Wiring (CTS or TRS) |

| #5. | Conduit Wiring |

Most Commonly Asked Questions:

Different Wiring Types You Need to Know or Types of Wiring Systems:

| Sr. No. | Types of Wiring Systems |

| #1. | Cleat Wiring |

| #2. | Lead Sheathed or Metal-Sheathed Wiring |

| #3. | Wooden Casing and Capping Wiring |

| #4. | Batten Wiring (CTS or TRS) |

| #5. | Conduit Wiring |

The Various Types of House Wiring and When to Use Them:

| Sr. No. | Type of Electrical Wiring |

| #1. | Cleat Wiring |

| #2. | Lead Sheathed or Metal-Sheathed Wiring |

| #3. | Wooden Casing and Capping Wiring |

| #4. | Batten Wiring (CTS or TRS) |

| #5. | Conduit Wiring |

Explain Different Types of Wiring Used in Electrical Installation:

| Sr. No. | Types of Wiring Used in Electrical Installation |

| #1. | Cleat Wiring |

| #2. | Lead Sheathed or Metal-Sheathed Wiring |

| #3. | Wooden Casing and Capping Wiring |

| #4. | Batten Wiring (CTS or TRS) |

| #5. | Conduit Wiring |

Like this post? Could you share it with your friends?

Suggested Read –

Nice workdone, thanks for the service.

Good job, sir thank you so much for sharing this knowledge with us

Found a good site whereby notes are well explained making a student understand easily

Thanks for providing such useful information.

Well done