When it comes time to connect any two wires, how do we connect them? We loosen the insulation at both ends, bend it together and wrap it with insulation tape. This system does not work when it comes to connecting numbers but we have to connect a closed wire.

But when you have to take a lot of output from one wire, the joint system is neither the right way nor the safe way. Terminal Block is used to connect this properly. So in today’s article, we will see what is Terminal Block and how many types it has.

What Is a Terminal Block?

A terminal block is also known as a connection terminal or terminal connector. Inside is a modular block attached to an insulated frame. Which helps us to connect one or more wires together safely and securely. It includes a clamping component and an operating bar.

A metal strip is included in the construction of the terminal block so that it can easily carry current. Which also provides support for connecting wires. The body has a mounting adjustment so that it can be easily mounted or unmounted by a PCB or mounting rail.

Most of the terminal blocks used in the market are usually modular, mounted on DIN rails, which allow an increase or decrease in the number of terminals as required. Due to the terminal connection, the joint of the wire can be kept properly and secure. And the wire can also be properly aligned.

Suggested Read: What is a Clamp Meter | Construction of Clamp Meter

Types of Terminal Blocks:

Terminal blocks can be classified on the basis of their structure, device type, and termination options.

| Sr.No. | Types of Terminal Blocks |

| #1. | Structure Type |

| #2. | Device Type |

| #3. | Power Distribution Blocks |

#1. Structure Type:

In Structure Type, it is divided into three types which are as follows:

- Single Level Pass-Through Terminal Blocks.

- Dual-Level Terminal Blocks.

- Three-Level Terminal Blocks.

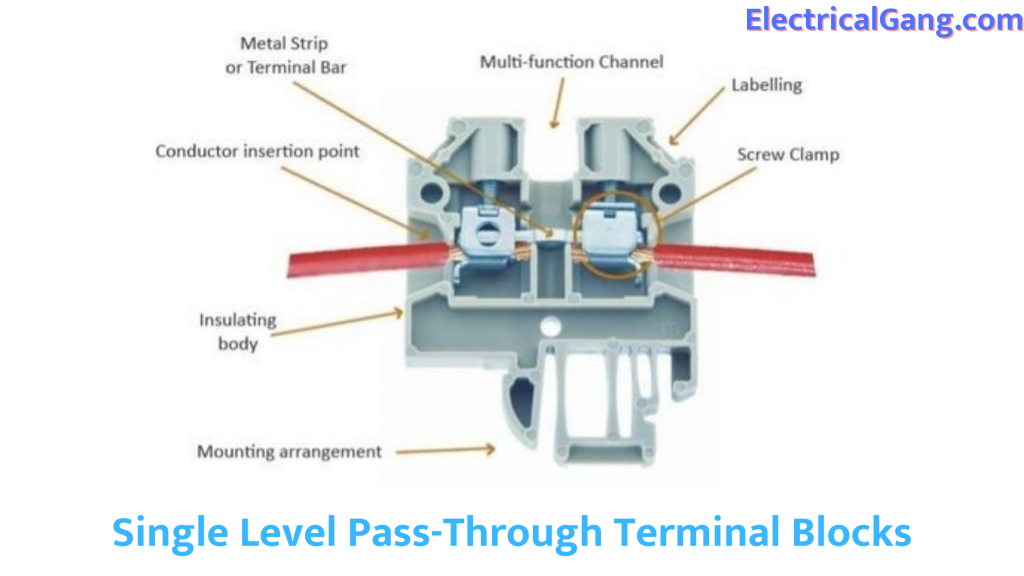

#1.1 Single-Level Pass-Through Terminal Blocks:

This system is used to connect two wires together. In another simple language, wire to wire connection is also known as a single feed terminal. This type of system is quite simple with one wire as the input and the other wire as the output.

#1.2 Dual-Level Terminal Blocks:

This system is typically used to save space. This block is the second level of the connection which is fixed on the first.

#1.3 Three-Level Terminal Blocks:

Like dual-level terminal blocks, we create an extra layer like this. The advantage of multilevel blocks is that many connections can be made in a single block.

Suggested Read: What is 2 Way Switch | 2 Way Switch Wiring | The Definitive Guide

#2. Device Type:

In Device Type, it is divided into five types which are as under:

- Ground Terminal Blocks.

- Fused Connection Terminals.

- Thermocouple Terminal Blocks.

- I/O Blocks And Sensor Blocks.

- Disconnect Terminal Blocks.

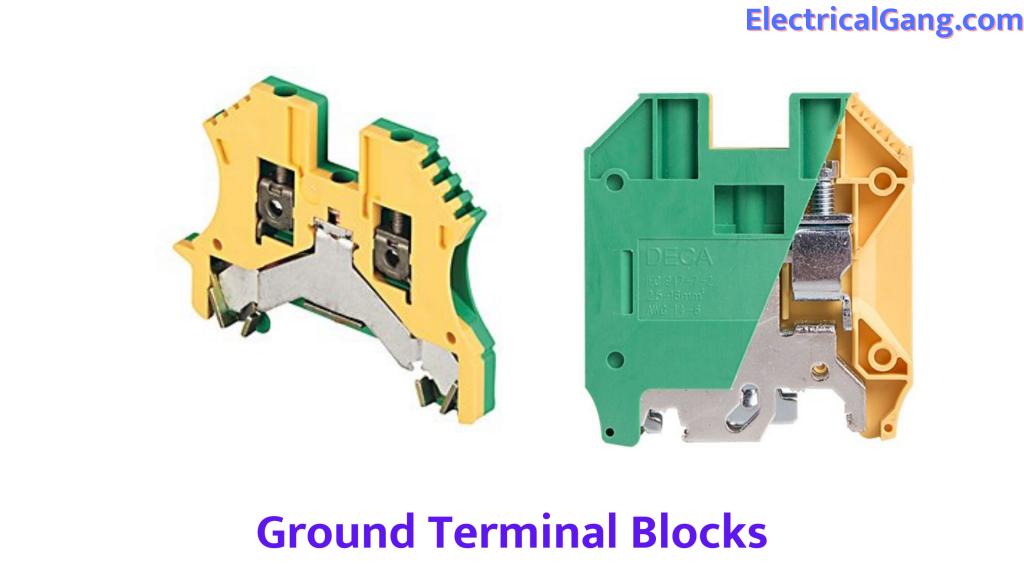

#2.1 Ground Terminal Blocks:

These blocks are similar in appearance to single-level feed-through terminals. The problem is that these blocks and the metal connection where the wire is completed depend on the panel or DIN rail on which the block is mounted.

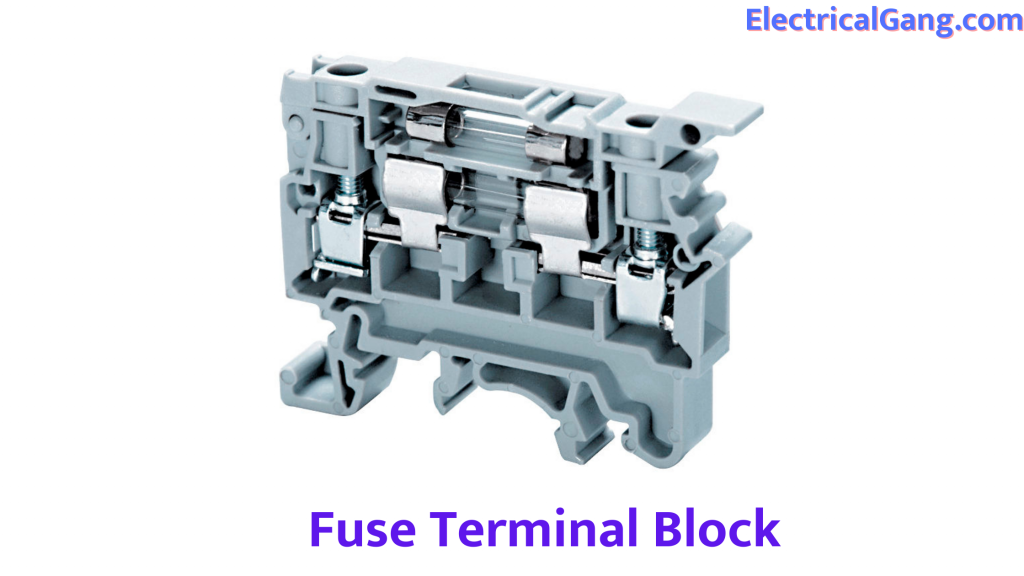

#2.2 Fused Connection Terminals:

This is similar to the pass-throw blocks with the object of the metal connection bar. Which is replaced with a fuse. That is why the wire connected to it is passed through the fuse to provide security to it.

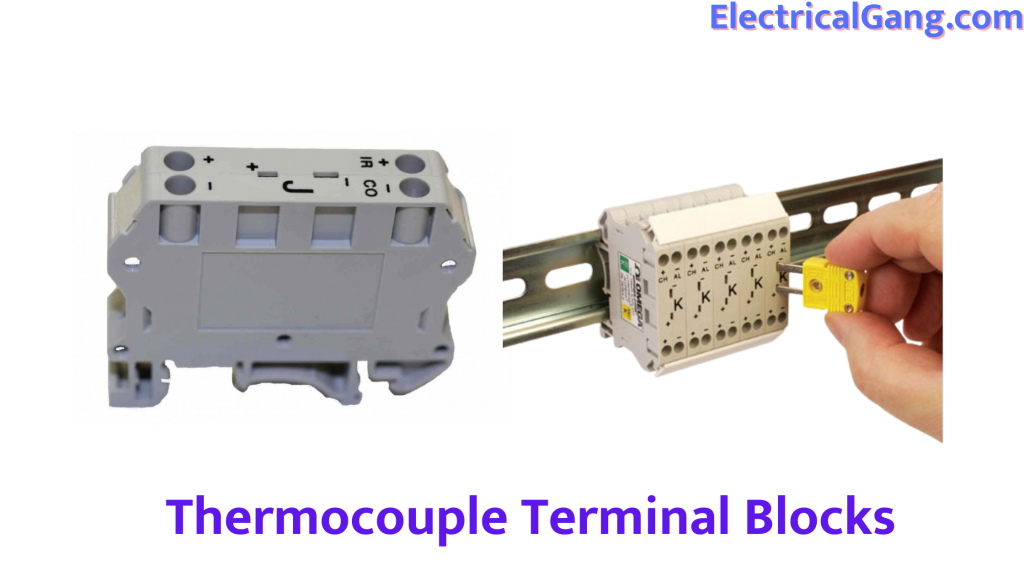

#2.3 Thermocouple Terminal Blocks:

Thermocouple Terminal Blocks are specifically designed to make thermocouple lead connections. Some thermocouple connectors clamp the thermocouple lead together on both sides of the block as required, thus removing the metal connection strip inside the block. In some Thermocouple blocks, a metal connection strip of the same size as the wire may be present.

#2.4 I/O Blocks And Sensor Blocks:

I/O Blocks are used to connect the device and the controller. While the sensor blocks easily handle three- or four-wire devices, such as near-sensors.

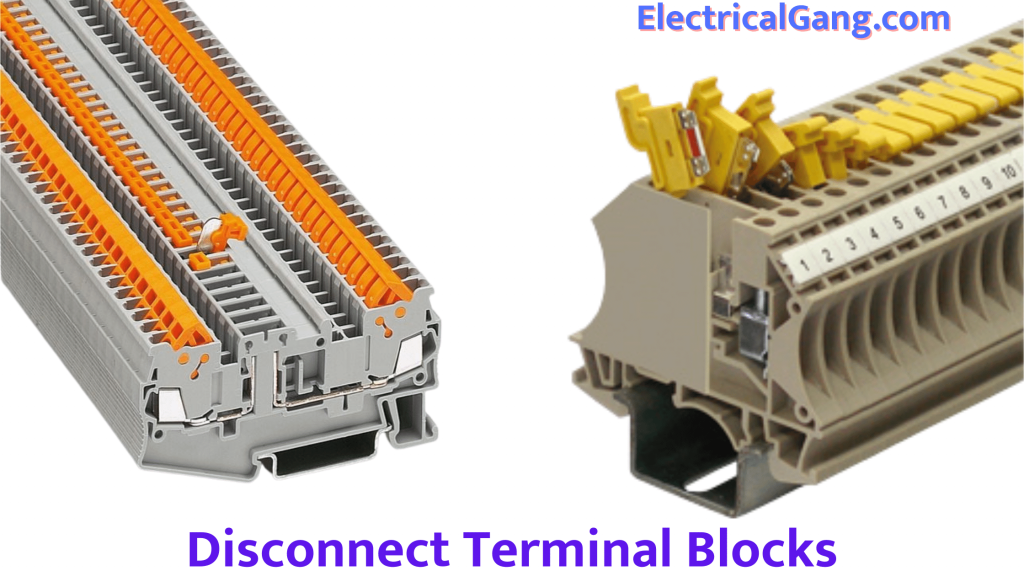

#2.5 Disconnect Terminal Blocks:

With the help of this block, the connection of the circuit is disconnected by lifting the lever switch. This block allows the wire to be easily connected and removed from the circuit apart from the cut function. Disconnect Terminal Blocks are also known as switch blocks.

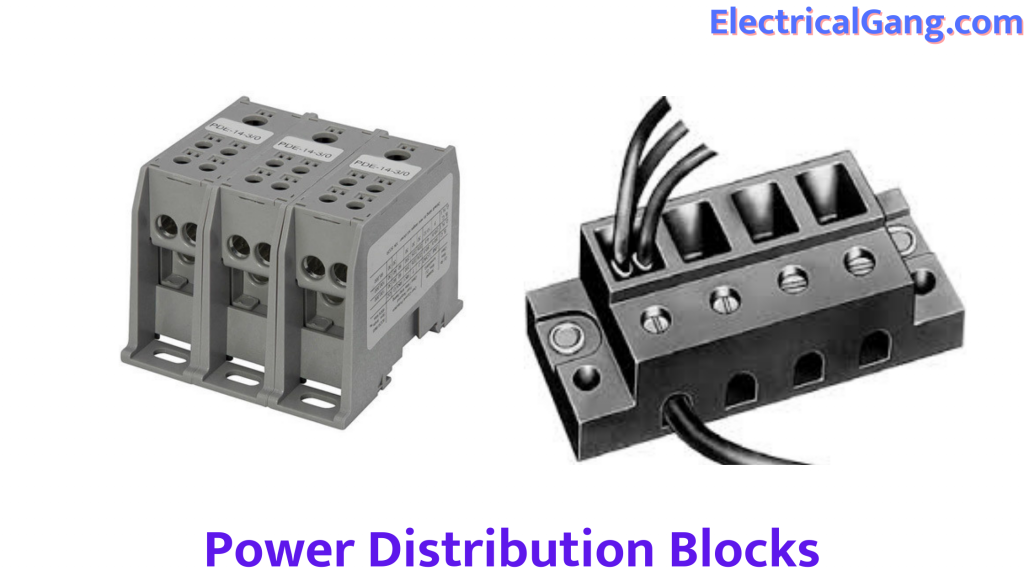

#3. Power Distribution Blocks:

This block can only be identified by its name. This is used in the distribution of electrical power. Multiple outputs can be easily taken with the help of one input through this terminal. This method is also the most suitable and economical and safe way to distribute.

In this method, as shown above, one input is given in power at a time and multiple outputs are provided in its output. The wire can be properly configured in the Matej Control Panel. So as to give it a neat, clean, and professional look.

Suggested Read: What is a Filter Capacitor? | Working of Filter Capacitor

Clamping Options In Terminal Blocks:

There are 5 ways to clamp in a terminal block which are as follows:

- Screw Terminal.

- Spring Clamp.

- Push-In Terminal Blocks.

- Insulation Displacement Connector (IDC).

- Barrier Terminal Block.

#1. Screw Terminal:

This type of method is the most common type of method under which the wire is easily fixed with the help of a screw according to the conductor strip alignment of the block in it i.e. tightened. The screw terminal method involves a very wide range of wire or conductor sizes.

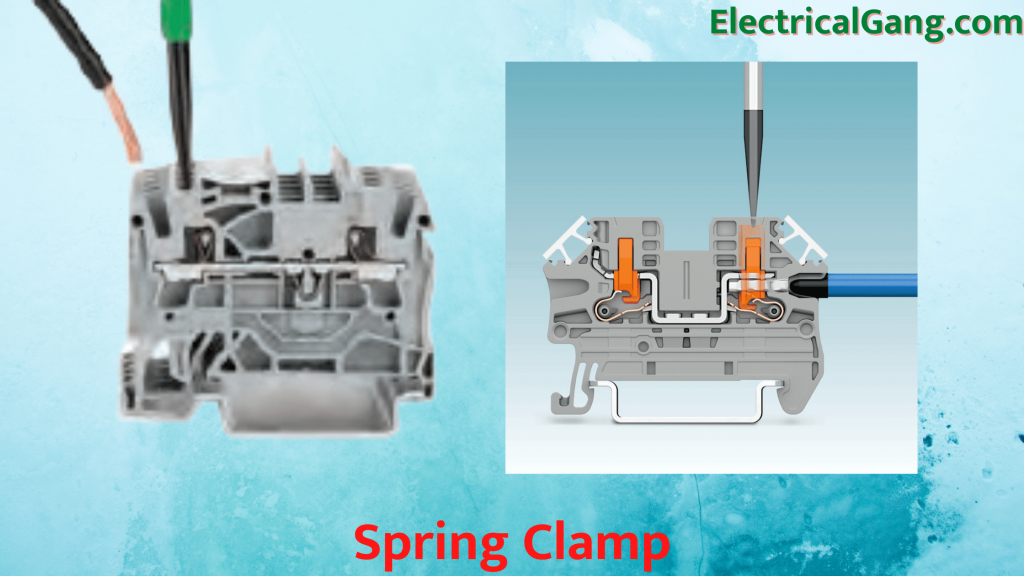

#2. Spring Clamp:

This method uses a spring to attach the wire to the terminal block. This type of method is of a slightly different type than the screw terminal. Spring Clamp is usually used for small wire sizes.

#3. Push-In Terminal Blocks:

Inside Push-In Terminal Blocks, you can only insert one wire. Large amounts of the ferrule are used in push-in terminals. The use of ferrule strengthens the ends of the wire. However, some push-in terminal blocks allow the insertion of a solid conductor or a helpless conductor directly by inserting a screwdriver into the release hole.

#4. Insulation Displacement Connector (IDC):

In this system, we do not need to cut or loosen the insulation of the wire. To make this contact, only the wire is inserted into it. Inside, two sharp metal blades of metal will cut the conductor properly to make proper contact with it.

#5. Barrier Terminal Block:

This terminal block is used where there is excessive vibration. This is connected to a spade or ring terminal. It is then bolted to the nut on the terminal block. So that any vibration in the machine will be affected but this wire will not be loose.

Suggested Read: What is a MOSFET | Construction of MOSFET | Working Principal of MOSFET

Advantages of Terminal Blocks:

The advantages of a terminal block are as follows:

- This cost is lower than other types of terminals.

- Saves time as it is not a long process like other processes.

#1. Reduce Space:

Space can be saved by using multi-level terminal blocks as it saves up to 50% of the space inside the panel. Because in multi-level blocks it is a multi-level circuit with one block.

#2. Increase Safety:

The other component of the circuit is grounded with the help of a terminal block to increase safety and security. The terminal blocks inside provide finger-safe connections to prevent jerks. The terminal block also provides a test point to add even more safety to the circuit.

#3. Easy Installation:

This can only be fixed with the help of a perpetual screwdriver or tester. It can be quickly connected and disconnected in any difficult situation. Terminal blocks are mainly used to connect electrical switches and outlets.

#4. Made of Copper Alloy:

Copper alloys are used in the construction of most terminals. Which uses a wire-like expansion coefficient designed for use. Using the same expansion coefficient helps prevent loosening due to different expansion rates. It also reduces rust.

Suggested Read: What is a Phototransistor | Construction of Phototransistor

Disadvantages of Terminal Blocks:

The disadvantages of the terminal block are as follows:

- The main disadvantage of this is that if it is placed in a vibrating area, the wire will come loose or come out. Properly fixed connections are also likely to be lost.

- Before selecting it, it should be checked whether the space we are going to use is suitable for facing it or not.

- Terminal blocks are also required for areas where it is needed. They always make better options where in-cab and non-essential wiring are used.

Most Commonly Asked Questions:

What Are Terminal Blocks Used For?

A terminal block is a modular insulated block that protects more than one wire at a time. The terminal block is used to secure or terminate the wire in the factory. In their most basic form, terminal blocks have many individual terminals arranged neatly in a long strip.

What Is a DIN Terminal Block?

DIN rails and channels are rack or box-mounted connection points to secure two or more wires in a block circuit or power bus. Some types may include single or dual disconnect fuse or switch features, feed-through capacity, grounding, built-in indicators and resistors, isolation, and circuit protection.

Screw Terminal Block:

Screw terminal or screw-type terminal blocks secure the wire against the conductor in the terminal block by tightening a screw that closes the clamp. Push Button. Push-button terminal blocks secure the wire against the conductor by a spring clamp that is opened by pressing a button.

Are Terminal Blocks Connected?

Terminal blocks are available as rows but only one wire is connected to each terminal. The most common method of connection in a terminal block is to use a screw in which the wire is inserted and then clamped using a screw.

Like this post? Could you share it with your friends?