A transformer is a static device whose use plays an important role in transferring power from one circuit to another. Due to the principle of electrical magnetic induction, this is possible without any change in its frequency.

There is also a change in voltage and current. The main function of a transformer is to increase or decrease the voltage in AC power. The transformer can be divided into two sections depending on its construction, one is the core type and the other is the shell type.

The core-type transformer consists of 2-limbs and 2-yokes in the magnetic core. While the shell type, it consists of 3-limbs and 2-yokes. So in today’s article, we will see what is a shell-type transformer, why such a type of transformer is constructed, the working principle, and much more.

Suggested Read: What is a Step-up Transformer | Construction of Step-up Transformer

What is a Shell Type Transformer?

The appearance of this transformer is rectangular in shape which consists of three essential parts like one core and two windings.

Whose diagram is as follows:

Thus two windings named primary and secondary are included which are arranged in one part of the transformer. The coil of this transformer can be wound in the form of a multi-layer disc where these layers are insulated from each other by paper.

Such transformers are used for low voltage and high ratings. Cooling in this type of transformer is not effective. The winding of such a transformer is distributed in a systematic manner so that its heat can be dissipated naturally.

This winding is also known as sandwich winding or disc winding, it has high mechanical strength but is just as difficult to maintain. The cooling system of the Shell Type Transformer uses forced air or forced oil.

Construction of Shell Type Transformer:

In a shell-type transformer, lamination is formed in the shape of “E” and “I”. These two pieces are aligned in opposite directions to each other so that the high reluctance at the joint can be reduced.

Alternate coats are stacked separately to get rid of the permanent joint. This transformer consists of 3 main limbs with total current flowing in the middle limb while the remaining 2 limbs have partial flux.

That is why the width of its middle limb can be increased to the outer part. In this, both windings of a transformer like low voltage and high voltage are formed on the middle limb.

The low voltage winding is arranged close to the core while the high voltage winding is formed in the outer part of the low voltage winding. So that the insulation cost can be reduced and it is arranged neatly between the main as well as the low voltage windings. The shape of such windings is mainly cylindrical and on it, Core laminations are placed.

Suggested Read: What is a Potential Transformer | Construction | Working | Types & Its Applications

Working Principle of Shell Type Transformer:

In Shell Type Transformer, both coils are twisted in the middle leg. This is because one winding is wound in the middle of it and the other winding is wound from the upper part of the first winding.

Doing so eliminates the possibility of leakage. Once the primary coil is stimulated it produces a flow so that it can cut the next coil. Therefore when producing current it immediately cuts the coil with low leakage to produce the required output voltage.

Advantages of Shell Type Transformer:

The advantages of Shell Type Transformer are as follows:

- Its short circuit strength is good.

- Mechanical and dielectric strength is more.

- Leakage magnetic flux control is good.

- Flexible design.

- Easy transport.

- The size of the transformer is compact.

- The cooling system is admirable.

- The outflow is protected from magnetic flux.

Disadvantages of Shell Type Transformer:

The disadvantages of Shell Type Transformer are as follows:

- Its repair work is difficult.

- Cannot provide natural cooling.

- Iron is used in its construction.

- Production costs will be higher due to labor costs.

Suggested Read: What is a Step-Down Transformer? | The Definitive Guide

Applications of Shell Type Transformer:

The applications of Shell Type Transformer are as follows:

- These transformers are used more for low-voltage applications including converters in electronic circuits as well as power electronics.

- This is used where low voltage is required.

- These transformers used in low-voltage applications may be less expensive due to cross-section area cores such as rectangles or squares.

Like this post? Share it with your friends!

Suggested Read –

- What is a Signal Isolator? | A Complete Guide

- Highway/Street Light Names And Functions

- How to Fix YouTube TV Freezing Issues in Easy Steps

- How to Solve LG Content Store Not Working Problem?

- What is a Phototransistor | Construction of Phototransistor

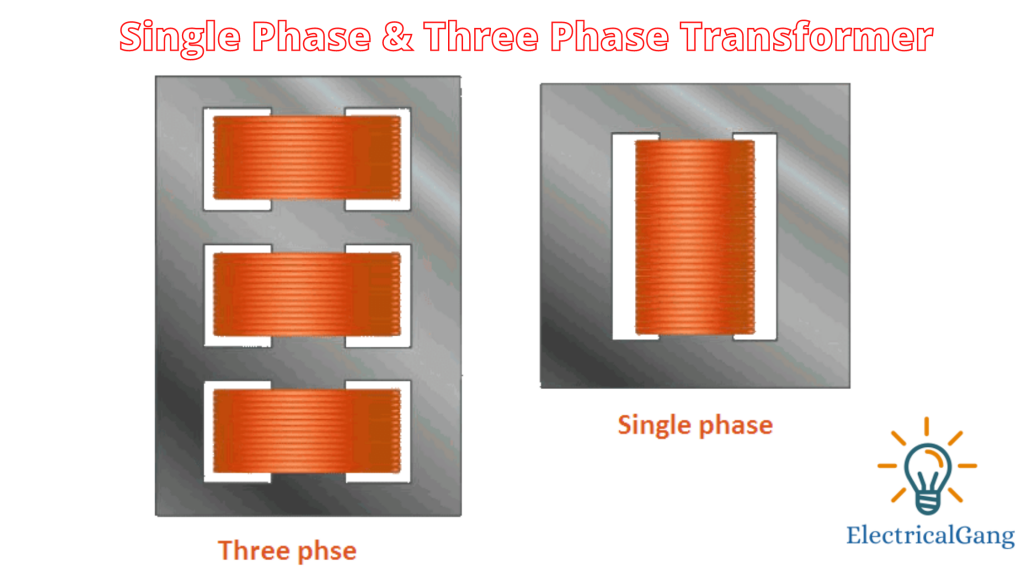

- What is a Single Phase Transformer | Construction of Single Phase Transformer